Stacking circumstances of various sizes and weights onto a pallet generally is a difficult process to perform. It’s nearly like taking part in real-life Tetris – though it may be enjoyable and difficult, folks naturally must decelerate and suppose: what to stack when, and the place? That prices companies cash. That’s the place automated combined case palletizing is available in.

Combined case palletizers pace issues up through the use of AI and clever sensors to stack combined circumstances sooner and extra constantly than any operator can.

On this weblog, we’ll offer you a deep dive into 5 methods combined case palletizing helps enhance the general provide chain, beginning with:

1. Boosting end-of-line effectivity

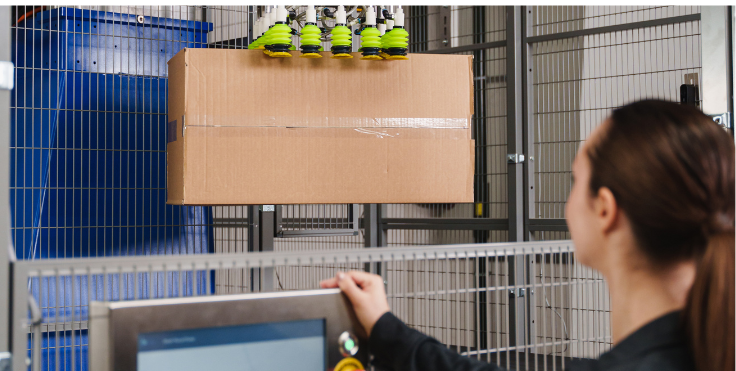

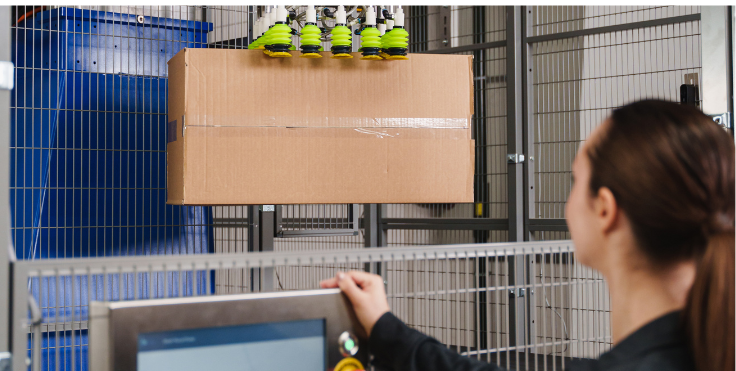

Operators manually palletizing combined circumstances always have to consider the way to place every case to maintain the pallet steady and use house effectively. However, robotic combined case palletizers use AI to course of knowledge and make fast stacking selections. The software program immediately calculates the optimum stacking sample – a lot sooner and extra constantly than a human can.

This not solely hastens the workflow, but additionally reduces downtime brought on by fatigue or errors — getting items out the door sooner and maintaining clients comfortable.

2. Chopping down the variety of traces you want

Most palletizing setups maintain traces separate so that every one handles merchandise of the identical measurement and weight.

Because of combined case palletizers, services can run a single line of various merchandise – not worrying in regards to the weight or measurement.

Having only one (or just a few) line(s) working merchandise with totally different sizes and weights dramatically reduces prices of infrastructure, upkeep, and total footprint.

3. Decreasing labor pressure and harm danger

Manually palletizing combined circumstances usually means repetitive lifting, generally in awkward methods. That provides up and might take a toll on employees over time, particularly when lifting heavy circumstances over the pinnacle.

Combined case palletizers are available in to take over the heavy, repetitive work, serving to cut back the danger of accidents on the ground. This doesn’t simply enhance employee security; it additionally helps corporations adjust to the brand new strict EHS rules, particularly in Europe.

4. Conserving pallets steady throughout transport

When a pallet travels lengthy distances, you wish to make certain it’s steady sufficient for the journey. Combined case palletizers don’t simply make selections primarily based on measurement, in addition they contemplate field weight and fragility to construct a balanced pallet.

This lowers the danger of injury throughout transit and helps forestall pallets collapsing on the warehouse ground.

5. Rising flexibility for retail and e-commerce

A T-shirt, sunscreen, and a pen, all in the identical order? Lately, that’s the norm.

Retail and e-commerce orders are getting smaller, extra frequent, and extra various. Combined case palletizers make it straightforward to stack totally different SKUs on the identical pallet, so there’s no want for separate traces or setups.

Whether or not it’s drinks, snacks, or digital merchandise, combined case palletizers adapts to totally different product sizes and stacking patterns on the fly.

Key takeaway

Combined case palletizing brings actual, measurable enhancements to warehouse operations. It reduces the variety of traces wanted, lowers your footprint, and cuts infrastructure prices, all whereas rising throughput and total output.

No shock, then, that increasingly more services are selecting combined case palletizers over conventional single-SKU methods.