At first look, it looks as if one robotic and one software program configuration ought to have the ability to palletize and depalletize merchandise from a pallet.

However is that basically the case? Are you able to deploy a single robotic in your facility to handle each stacking and unstacking merchandise, or do these two duties require totally different options?

Contemplating the variations in placement inside a facility and the distinctive necessities of every process, we are able to come to a greater understanding of those two automation roles.

On this article, you’ll acquire a clearer view of what’s required for each procedures, and which strategy makes probably the most sense on your logistics.

Let’s dive in, beginning with…

The definition of palletizing

Palletizing is the method of systematically stacking packaged items (resembling taped containers or crates) on a pallet, able to be shipped.

Robotic palletizing takes it a step additional through the use of robotics to deal with the duty, both stacking merchandise layer by layer or unit by unit.

In some amenities, palletizing continues to be accomplished manually. An worker lifts packaged merchandise from the top of the manufacturing line and stacks them onto an empty pallet. That is bodily demanding work, and it’s no shock that worker turnover is often excessive in these environments.

Nonetheless, as automation continues to rise and logistics corporations face ongoing labor shortages, robotic palletizing is changing into extra outstanding. It’s particularly useful for corporations with excessive throughput and a must get merchandise out the door quick.

The definition of depalletizing

Depalletizing is precisely the alternative of palletizing; it’s the method of unloading packaged items from a pallet. This often occurs when a freight truck arrives filled with pallets that should be emptied.

From there, the merchandise may be positioned onto a conveyor belt at the beginning of the manufacturing or manufacturing line or onto one other pallet (a course of often known as repalletizing).

As you’ll be able to think about, this process may be very bodily demanding on the workers, continuously lifting and inserting merchandise onto conveyor belts for hours on finish every day.

The similarities between palletizing and depalletizing

Sure, there are some similarities between palletizing and depalletizing, and it’s value highlighting these earlier than leaping into the variations:

- Each functions may be accomplished with the identical robotic. Considered one of our palletizers, the Good Combined Case Palletizer, can simply deal with each palletizing and depalletizing duties.

- They’re each categorized as pick-and-place jobs: very repetitive and monotonous work nobody desires to do.

- They’re typically an enormous hurdle to manufacturing and logistics amenities, primarily as a result of inefficiencies triggered if these duties are accomplished manually.

- The set up process for each functions takes across the similar time and follows the identical integration process. The one distinction is {that a} depalletizer wants a top-mounted digital camera for imaginative and prescient, which provides a bit extra time in comparison with a palletizer.

Key variations between palletizing and depalletizing

Now that we’ve mentioned the similarities between palletizing and depalletizing, let’s check out the variations:

Depalletizing challenges

When a robotic stacks a pallet with equivalent containers, it is aware of precisely the place to put them because of predetermined stacking sample know-how. This implies the machine, even with no imaginative and prescient system, can choose up the packaged product and know precisely the place to put it.

There may be nonetheless some considering concerned, like figuring out the best spot to put the product. However for probably the most half, for a single SKU palletizing resolution, it’s all predetermined.

Combined case palletizing often doesn’t use imaginative and prescient to put merchandise on a pallet however depends on clever software program to determine the very best stacking sample. Imaginative and prescient may be utilized for real-time validation or changes, but it surely’s not an absolute requirement.

Nonetheless, depalletizing is a little more sophisticated due to…

Gadgets shifting throughout transit

Throughout transit from one facility to a different, merchandise can shift and transfer—particularly in the event that they weren’t secured nicely sufficient with shrink wrap. This may trigger issues for a visionless robotic, which depends on selecting up items from a precise place. If the merchandise have moved even barely, the robotic will doubtless encounter an error and received’t have the ability to do its job correctly.

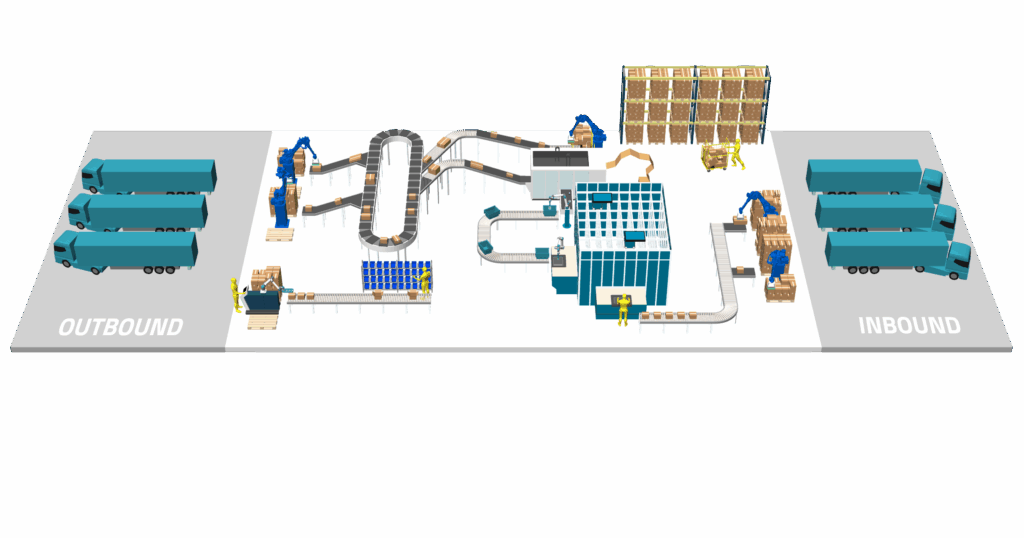

Completely different areas and processes in your facility

Generally, palletizing and depalletizing processes occur in numerous areas of the ability. Palletizing occurs on the finish of the method, after packing circumstances, sealing, and taping, when the product is able to be positioned on a pallet and shipped.

However, depalletizing occurs in the beginning of a facility’s course of, within the inbound section. Relying on the kind of facility, this often occurs when packaged merchandise arrive and should be unpacked and sorted to start out their journey by the manufacturing line.

Typically, two robots, one dealing with the palletizing course of and one handing the depalletizing course of, can work facet by facet in the identical location within the facility.

However that will depend on the kind of resolution a facility wants. You may contact us right now for a free, personalized resolution for your corporation.

The right way to resolve if you happen to want a palletizing or depalletizing resolution

One of the vital widespread questions we get is that this: ought to I begin automating with a robotic palletizer or depalletizer?

The reply relies upon solely in your facility’s wants.

Begin by asking your self these questions: –

- The place do bottlenecks often happen in my course of? At first of my line or on the finish of it?

- What’s my throughput requirement; Do I would like quick stacking or quick unstacking?

- Am I coping with labor shortages in a single particular space?

- Do I would like the identical robotic to do each duties?

Check out our palletizing and depalletizing resolution pages. When you nonetheless have questions or would love extra details about both resolution, be at liberty to contact our specialists.

In Quick

Palletizing and depalletizing each contain shifting packaged items on and off pallets. They share similarities in being repetitive, bodily demanding duties that may be automated.

Nonetheless, the principle variations come all the way down to the place they slot in your course of and what the machine must do to execute the applying efficiently.

Robotic depalletizing often requires imaginative and prescient with a view to do it proper, whereas automated palletizing sometimes doesn’t.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s developments right now: learn extra, subscribe to our publication, and turn into a part of the NextTech neighborhood at NextTech-news.com