A bicycle wheel with ropes as a substitute of spokes looks like a prescription for disaster, however somebody has managed to design one which rolls, retains pressure, and might assist the load of a rider touring over rugged terrain. The tip impact is beautiful, midway between the DIY inventiveness of a yard shed and a genuinely progressive rethinking of how wheels work.

Adam from TartyBikes spent an eternity in his storage, fiddling on his prototype for lots of of hours earlier than lastly assembling a working rope-spoke wheel. For inspiration, he went to industrial supplies equivalent to Berd spokes, that are ultra-high-molecular-weight polyethylene ropes used to fabricate wheels which are lighter and stronger than metal spokes. In fact, at a premium value. So Adam determined to aim creating his personal model at residence with no matter components and bobs he might discover simply.

RANHOT Electrical Bike for Adults, 750W/1000W Peak Motor,28MPH, 48V 13Ah Lithium Battery, 25-45 Miles…

- Basic retro design, fashionable energy: Expertise the proper mix of timeless model and fashionable know-how. Our electrical bikes function a smooth 20-inch…

- Highly effective efficiency for each journey: Outfitted with a sturdy 48V 750W (1000W peak) brushless hub motor, this e-bike ship speeds as much as 28 MPH. The…

- All-terrain functionality & superior consolation: Deal with any path with confidence! The 20″×4.0″ extensive snow tires and entrance suspension fork take in bumps and…

He selected the Robline DM20, a nautical rope manufactured of the identical ultra-high-molecular-weight polyethylene because the industrial Berd spokes. The fabric floats, resists put on and tear, and principally stays place beneath a load. Right here’s the kicker: every size of that rope can face up to round 450kg of pure pressure earlier than fraying moderately than snapping. That’s vital as a result of each spoke in a wheel is consistently beneath pressure; the rim is simply suspended from the hub like a miniature suspension bridge.

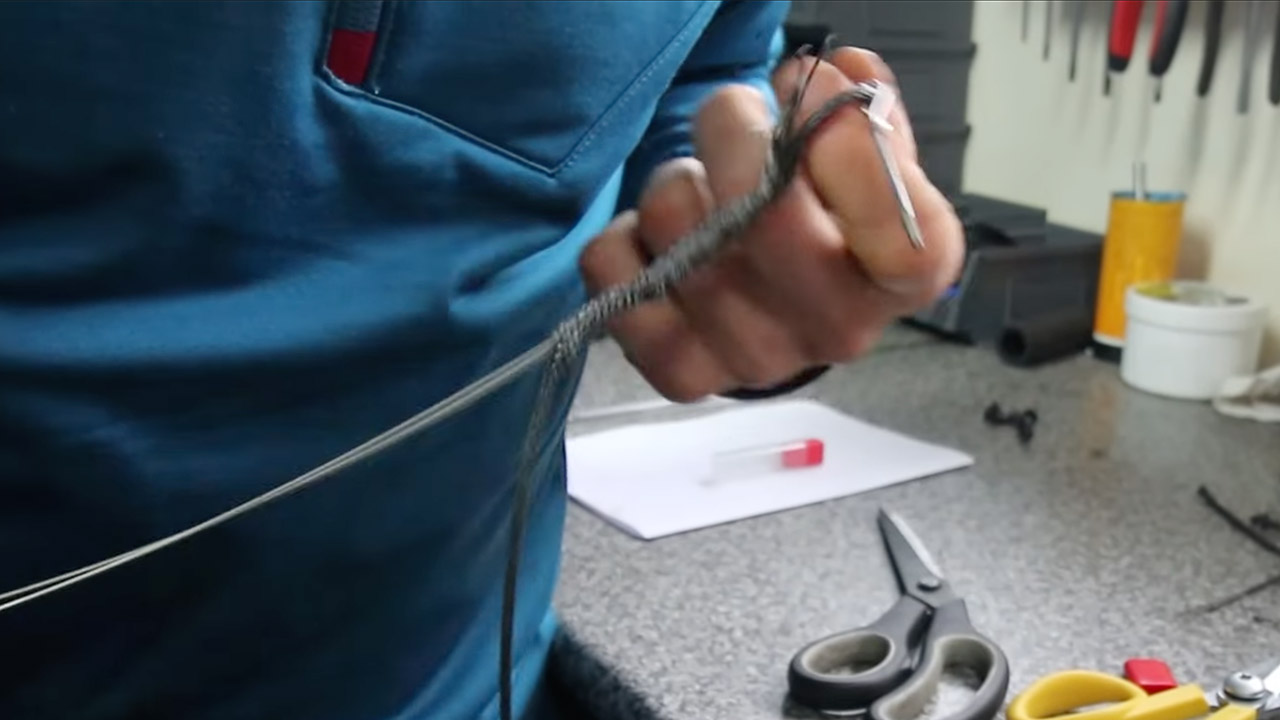

Metal spokes, in fact, have to be exactly minimize to size, threaded via the hub and rim, and tensioned with the small metallic nipples. In distinction, rope requires a complete totally different technique. Adam devised an answer by making little loops on the hub finish with extraordinary stainless-steel Sapim Race spokes. He bent the spoke right into a clear 180-degree loop on a particular jig, twisted one finish to the opposite for grip, floor down the twist flush, and welded the union with silver solder, making use of flux and heating it up good and sizzling to provide that cherry-red glow. After making use of the solder, he immersed the loops in a caustic soda answer to take away any corrosive residue.

On the rim facet, he utilized a splicing technique he had discovered whereas crusing. He shortened the top of the rope by slicing away the strands over round 100mm till only one strand remained, then tucked that tapered part again into the rope’s hole heart. And that half acts like a Chinese language finger lure: pull on the rope, and the skin braid tightens straight up across the hid core, forming a joint that holds virtually your entire energy of the rope with none knots. The spliced finish is then guided via a traditional spoke nipple on the rim. Double-square nipples offered him extra wiggle room to fine-tune the strain, compensating for the rope’s modest stretch when beneath pressure.

Lacing follows a typical three-cross design, and a single piece of rope is securely weaved between the hub flanges, with a hitch that holds every part in place as you improve the pressure, thereby reworking one rope into two opposing spokes. That makes issues neat, with fewer splices to cope with, whereas nonetheless maintaining your entire wheel correctly balanced. The method of getting every part arrange within the appropriate pressure happens in phases. As a result of rope stretches way over metal when subjected to the identical drive, Adam designed the wheels to be a number of millimeters quick and allowed the fabric to settle in in the course of the preliminary pulls. When it got here to getting it excellent, he merely relied on really feel and evenness of pluck; metal and metallic reply otherwise relating to damping vibrations, so excellent numbers aren’t sufficient.

The ultimate entrance wheel, which consists of a 24-inch downhill rim, an Business 9 hub, and a Lightbicycle carbon rim, weighs roughly 700 grams. If he had used metal spokes and nipples for the an identical construct, we’d be an extra 80 grams. On the bike, the high-frequency buzz from tough surfaces has been changed by a quiet, compliant journey that merely filters out any chatter and should even help reduce arm pump on lengthy descents.

[Source]

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a world community of future-focused thinkers.

Unlock tomorrow’s tendencies as we speak: learn extra, subscribe to our e-newsletter, and turn out to be a part of the NextTech neighborhood at NextTech-news.com