A DIY steel 3D printer powered by a laser welder brings industrial-grade additive manufacturing far nearer to the storage than anybody imagined. Maker Cranktown Metropolis acquired a 2000-watt fibre laser welder from Skyfire and put in it on an outdated 3D printer body salvaged from a defunct insole-printing enterprise. The final word result’s stable steel objects produced layer by layer with welding wire because the “ink,” demonstrating that very sturdy lasers usually present in factories can now be used on tasks at house.

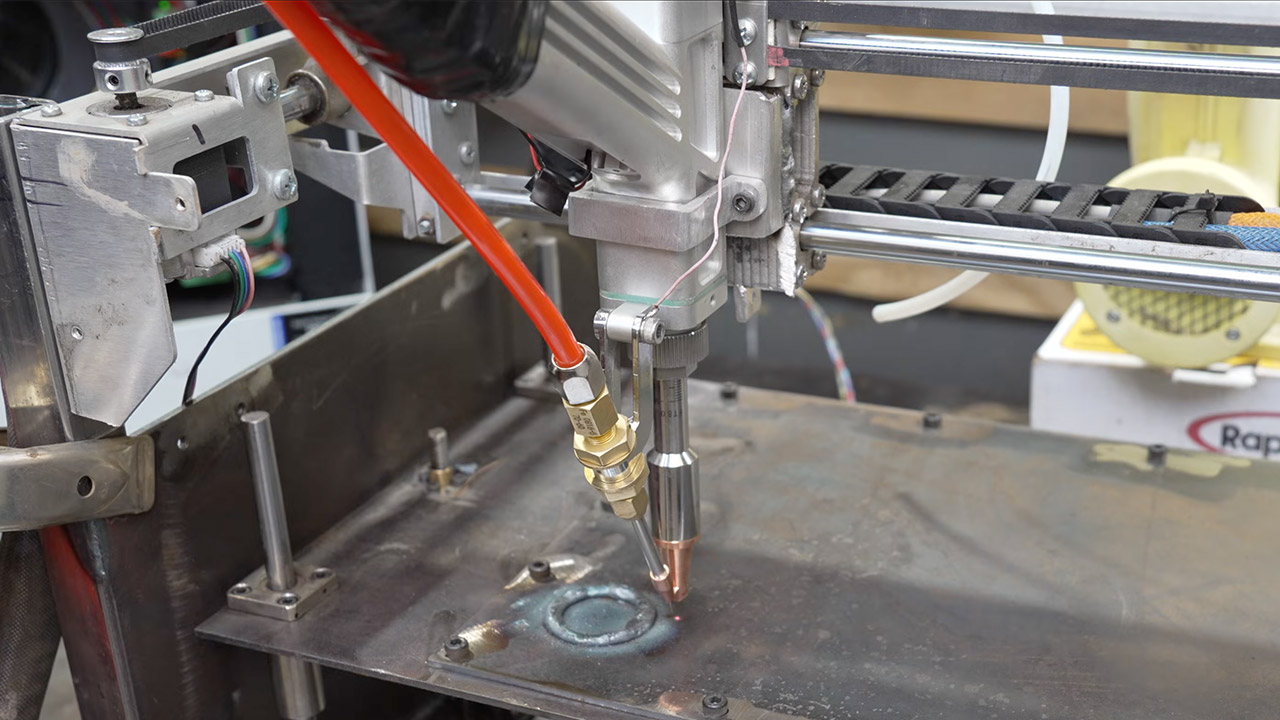

Cranktown Metropolis started with two outdated dual-head 3D printers that they bought for affordable on Fb Market. One machine was damaged in half to function the muse for the movement system, and the unique gantry was considerably upgraded with a brand new metal body bolted collectively for added stability, because you need the factor to maneuver easily. The laser welding torch changed the usual print head and was secured with a bespoke plate and straps. The stepper motors and linear bearings dealt with the movement, whereas an historical CNC pc working LinuxCNC was introduced again to life to deal with all of the controls. They employed a CoreXY kinematics system to make sure that it was quick and exact alongside the X and Y axes.

Bambu Lab A1 Mini 3D Printer, Help Multi-Colour 3D Printing, Set Up in 20 Minutes, Excessive Velocity & Precision,…

- Excessive-Velocity Precision: Expertise unparalleled velocity and precision with the Bambu Lab A1 Mini 3D Printer. With a formidable acceleration of 10,000…

- Multi-Colour Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make…

- Full-Auto Calibration: Say goodbye to handbook calibration hassles. The A1 Mini 3D printer takes care of all of the calibration processes robotically,…

The laser melts tiny welding wire as it’s fed regularly into the torch, and the top attracts out every layer. The 2000-watt fibre laser gives ample energy to fuse the molten materials to the earlier layer or the development plate. Initially, they used compressed air for shielding, however the outcomes have been poor and vulnerable to cracking, in order that they switched to nitrogen, which helped however triggered some security considerations owing to oxygen displacement. Ultimately, Argon offered the cleanest and strongest outcomes with significantly fewer flaws.

Warmth administration turned a significant challenge as a result of the highly effective laser was heating the construct plate so shortly that it was prone to warping and binding to the Z-axis Gantry. A giant cooling fan taken from an inflatable bouncy fort setup arrived on the scene to vent air between layers and preserve temperatures in test. They changed the earlier building plate with a thicker (3/16 inch) one which was securely fixed with machine screws and leveled utilizing precision washer stacks. The wire feed triggered the primary critical points; when the fabric started to stay to the nozzle or floor after deposition, they solved it by including a brief pause at layer ends, retracting the wire, and implementing Z-hop motions to raise the top cleanly.

The preliminary outcomes have been a little bit of a jumble, with inconsistent fusion and the occasional bead right here and there, however as they altered the G-code (randomized layer begins to keep away from seams and delays to let the molten swimming pools to type correctly), the method started to return collectively. They quickly found that they might print extra bold shapes; a sphere demonstrated the overhang capabilities, and a chess pawn captured some lovely particulars in its base and tapering, however the actual standout was a vase with easy flowing sides that had apparent however affordable layer traces.

[Source]

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s tendencies as we speak: learn extra, subscribe to our publication, and turn out to be a part of the NextTech neighborhood at NextTech-news.com