In a 2,000-square-metre facility in Nsukka, Enugu State, in southeastern Nigeria, engineers assemble airframes, take a look at management programs, and fine-tune battery modules to show some extent: Nigeria can construct exhausting tech.

Arone Applied sciences, based in 2018 by AI engineer Emmanuel Ezenwere, is likely one of the few Nigerian startups trying to fabricate drones and modular photo voltaic vitality programs regionally. The corporate is betting on {hardware}, from autonomous aerial logistics to moveable photo voltaic programs, constructed largely in Nigeria.

That ambition is ready to scale by a ₦12.95 billion ($9.52 million) partnership with the state-owned Institute of Administration and Expertise (IMT), Enugu. Over the subsequent 4 years, each companions plan to determine what they describe as Nigeria’s first tech manufacturing plant devoted to defence, aerospace, robotics, AI, and renewable vitality, a complete industrial hub constructed inside the IMT campus.

“We’re constructing options that allow vitality safety and allow good dwelling,” Ezenwere instructed TechCabal in an interview. “Our main focus is vitality safety and synthetic intelligence.”

Arone was based “manner earlier than AI turned horny,” as Ezenwere places it. The corporate’s early mission was sensible: fixing Nigeria’s last-mile healthcare supply downside.

Arone’s journey started in 2018 with a ₦3 million ($2,200) grant from Roar Nigeria, the College of Nigeria, Nsukka’s tech hub, alongside a $5,000 angel funding. It later raised a $100,000 seed spherical from Energia Ventures and AfriClim Accelerator, in addition to investments from angel traders.

For a corporation that after watched its capital evaporate in a drone crash, the ₦12.95 billion ($9.52 million) manufacturing partnership marks a dramatic evolution.

Fixing the last-mile downside

Nigeria has greater than 30,000 main healthcare centres, many situated in rural communities with poor highway infrastructure. Deliveries of blood, vaccines, and emergency remedy can take hours, typically too lengthy.

Arone’s reply was autonomous drones able to carrying as much as 5kg of medical provides over distances of as much as 200 kilometres. Via a community of “Avports”, autonomous car ports stationed at blood banks and distribution hubs, drones can take off, ship to distant clinics, and return with out human intervention.

A visit which may take one hour and fifteen minutes by highway could be accomplished in about quarter-hour by drone.

The corporate’s early cargo drone, able to carrying 20kg, was among the many first of its form in Nigeria. Its maiden flight in 2019 was profitable. The subsequent one crashed.

“We have been thrilled with the accomplishment,” Ezenwere recalled. “However the actuality was that the crash value was better than the capital we had raised.”

The setback compelled the group to rethink the right way to construct {hardware} in Nigeria. As an alternative of chasing excellent, completed merchandise, Arone started breaking programs into manageable modules, refining and iterating step by step. It additionally pivoted towards niches that might maintain income, together with safety purposes.

Right this moment, Arone claims it really works with the Nigerian Defence Analysis and Improvement Bureau and the Air Drive, supplying drones for surveillance and safety use instances.

Manufacturing in a troublesome atmosphere

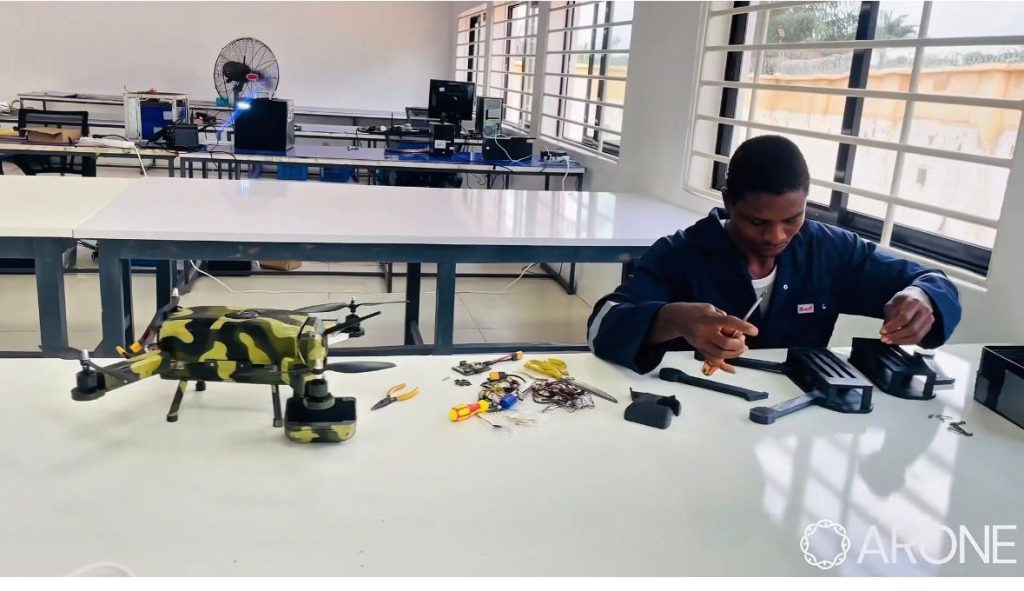

Arone engineers at work within the Nsukka manufacturing facility. Picture supply: Arone

Constructing {hardware} in Nigeria will not be for the faint-hearted. Ezenwere describes a panorama the place each layer have to be questioned: expertise, supplies, capital, and market readiness.

“It’s not simply manufacturing,” he stated. “It’s the total meals chain, analysis, growth, manufacturing.”

When requested what “manufacturing” means for Arone, Ezenwere is cautious. No fashionable {hardware} firm builds all the pieces from scratch. However Arone says over 50% of its drone programs are indigenous.

The corporate designs and builds its airframes regionally, develops its management programs and software program in-house, and owns its AI fashions. Motors and batteries are nonetheless sourced externally, although the corporate says it’s working towards deeper localisation.

For its AI surveillance platform, QView AI, Arone owns your entire software program stack. The fashions mix custom-built programs with open-source parts, however with out third-party possession of the ultimate product. For enterprise purchasers, together with authorities establishments, the system could be deployed on-premise, scaling from a couple of gigabytes of RAM to terabytes, relying on necessities.

The technique reduces publicity to forex fluctuations and import markups, although not totally. “We’re uncovered,” Ezenwere admits, “however the stage of publicity is lowered.”

The associated fee benefit is critical. Arone’s Aurora drone, outfitted with thermal imaging capabilities for night time surveillance, prices round ₦3 million ($2,190). Comparable international drones with related specs can value upwards of $10,000.

“Why would somebody fascinated about safety purposes select to spend $10,000 after they can get the identical functionality regionally?” he requested.

Powering past drones

As Arone scaled its drone operations, it encountered one other Nigerian constraint: electrical energy.

That constraint birthed its second division: modular vitality programs. Its flagship product, Luminar 2.0, is a transportable, suitcase-sized photo voltaic vitality system designed to energy home equipment and important gear throughout outages.

The biggest Luminar mannequin delivers 3KVA and 2000 watt-hours, sufficient to energy a microwave, tv, and fan, ample for a middle-sized family. The programs use lithium iron phosphate (LiFePO4) batteries with good thermal administration, designed to face up to temperatures as much as 45°C and function for 5 to seven years.

As of late 2025, Arone says it has deployed over 1.35 MWh of modular vitality programs throughout all 36 states in Nigeria. Vaccine fridges are among the many important home equipment powered by the programs throughout blackouts.

Power safety, Ezenwere argues, is inseparable from technological independence. “It’s a mission for us to construct an ecosystem that may remodel Nigeria from a consuming nation to a producing nation.”

Underneath the partnership with IMT, Arone will present mental property and product designs, whereas IMT gives funding and infrastructure. Manufacturing targets embody 5,000 Aurora drones per 12 months, over 30,000 Luminar vitality programs yearly, and greater than 200 QView AI servers.

Past manufacturing output, the partnership goals to coach greater than 20,000 college students. The aim will not be merely to provide manufacturing facility employees however future industrialists.

“The target is not only to coach manufacturing employees,” Ezenwere stated. “It’s to coach individuals who will ultimately construct different industries.”

Arone’s facility, situated close to the College of Nigeria, Nsukka, initially needed to transport college students by bus every day to construct sensible publicity. Many engineering graduates, he notes, find yourself pivoting to net growth or unrelated software program expertise as a result of there are few alternatives to apply {hardware} engineering.

“It’s not their fault,” he stated. “There’s no consumption of that expertise.”

By embedding manufacturing and coaching inside the IMT partnership, Arone hopes to create a pipeline the place engineering levels translate into actual industrial output.

Implementation, Ezenwere says, has already begun, with a month-by-month roadmap spanning 4 years.

For Arone, success isabout shifting Nigeria’s industrial trajectory.

If the plan works, Enugu may develop into a hub for indigenous aerospace and vitality manufacturing. 1000’s of scholars would achieve hands-on {hardware} expertise. Safety companies and healthcare suppliers may rely much less on imported programs. And Nigeria would inch nearer to producing extra of what it consumes.

In a rustic the place software program dominates the startup narrative, Arone is making a contrarian guess that actual transformation could require factories as a lot as code.

“We care so much about sustainability,” Ezenwere stated. “Not simply sustaining our firm, however remodeling Nigeria.”

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the most recent breakthroughs, get unique updates, and join with a world community of future-focused thinkers.

Unlock tomorrow’s developments as we speak: learn extra, subscribe to our e-newsletter, and develop into a part of the NextTech group at NextTech-news.com