The CHAMP (Chewy Autonomous Cell Selecting) Problem, developed by Chewy in collaboration with MassRobotics, was created to handle a persistent and technically complicated limitation in warehouse automation: enabling absolutely autonomous robots to deal with giant, heavy, and non-rigid objects inside dense and dynamic success heart environments. This stuff—usually weighing over 40 kilos and exhibiting variable shapes, floor textures, and ranges of deformability—current a multi-layered manipulation problem. Their irregular geometry and low structural stiffness scale back the effectiveness of standard suction or parallel-jaw gripping strategies, whereas inconsistent stacking and presentation on pallets additional complicate object recognition and grasp planning.

Past the manipulation process, the CHAMP Problem demanded system-level integration: robotic platforms wanted to navigate by aisles as slender as 20 inches, coordinate with reside warehouse operations, and place picked objects into transport containers of various dimensions, probably with mixed-product contents. The problem known as for embodied AI options able to perception-driven decision-making, strong grasp adaptation, and secure operation in collaborative settings. To help growth, the Chewy Robotics workforce offered contestants with photographs and movies of success operations, entry to the Chewy robotics lab, and a complete NVIDIA Omniverse simulation bundle, together with a digital twin of the warehouse and 3D belongings for a subset of Chewy’s product line. The problem aimed to allow groups to validate their options, whether or not as simulation-based prototypes or as bodily methods able to work together with the actual world.

Twelve international groups have been chosen to take part within the CHAMP Problem, representing a various mixture of early-stage startups and unbiased robotics engineers. Over a number of months, these groups engaged in shut collaboration with members of the Chewy Robotics workforce who delivered steering on operational constraints, success workflows, and system-level necessities. This hands-on mentorship enabled contributors to refine their options past the lab, incorporating real-world logistics concerns into their autonomous robotic methods. The ensuing prototypes mixed {hardware} innovation with superior notion, movement planning, and manipulation methods tailor-made to the problem’s calls for. This collaborative effort not solely superior every workforce’s technical strategy but in addition illuminated important gaps in warehouse automation that stay unsolved, providing Chewy and the broader trade a clearer view of what’s wanted to deploy robotics in high-throughput, constrained environments.

After a radical analysis, Chewy has named:

Winner: Black-I Robotics

Black-I Robotics, a Massachusetts-based MassRobotics resident with a powerful basis in defense-grade cell manipulation, earned the $30,000 grand prize for delivering a classy, full-stack autonomous selecting system. Their answer featured a sturdy cell base paired with a 6-DOF industrial arm, leveraging customized multi-modal finish effectors engineered to deal with giant, deformable, and heavy SKUs.

Black-I’s strategy built-in AI-driven notion with high-confidence object detection and pose estimation, enabling exact greedy of non-rigid objects stacked on blended pallets. The robotic demonstrated full-facility navigation utilizing fiducial markers and SLAM, dynamic impediment avoidance for secure operation alongside warehouse associates, and seamless integration into downstream workflows by way of autonomous field placement.

Their constant iteration, deep technical execution, and supply of an entire cell manipulation pipeline set their entry aside, assembly the problem’s core calls for for autonomy, adaptability, and deployability in constrained warehouse environments.

Runner-Up: Breezey Machine Firm

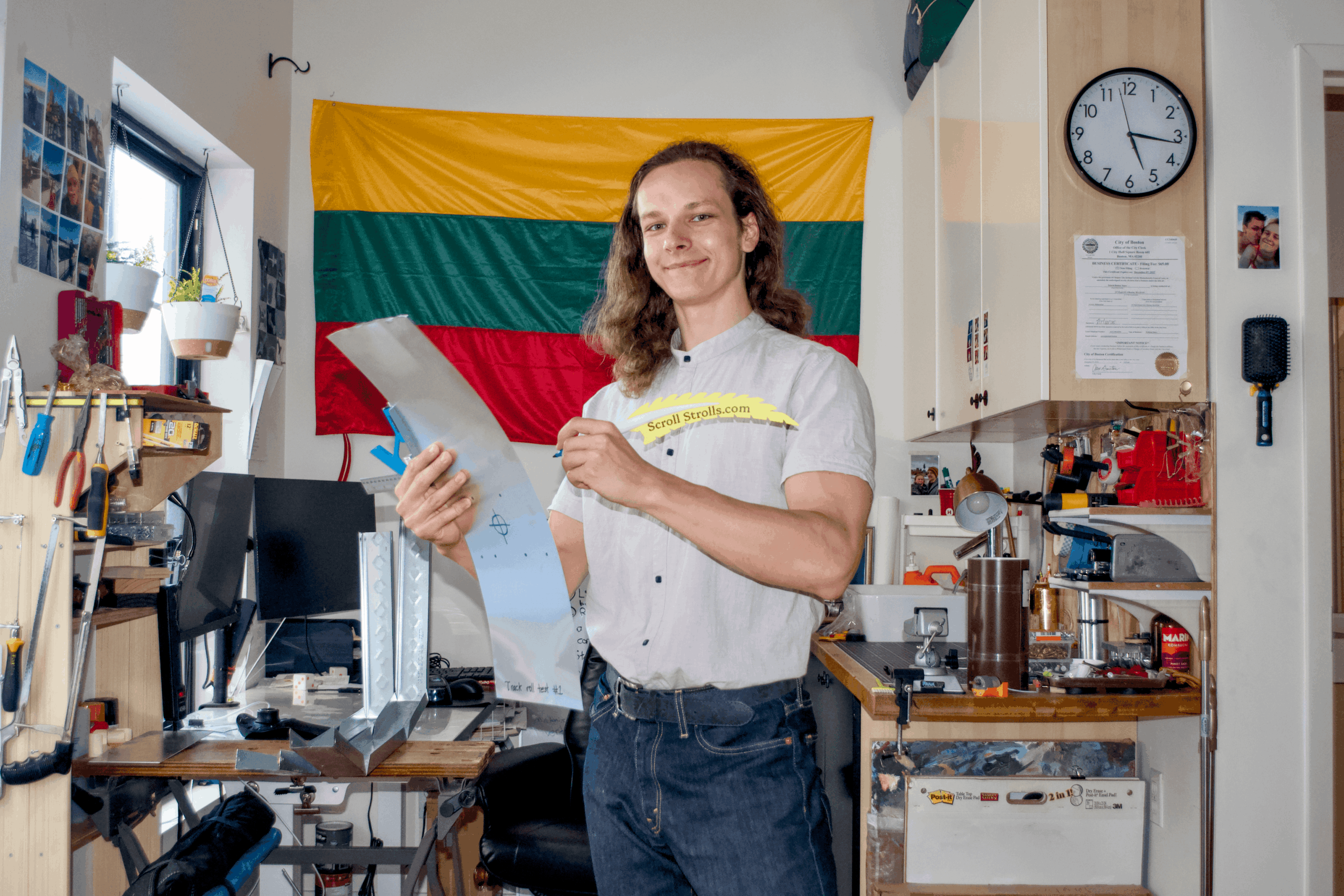

Breezey Machine Firm, a workforce of unbiased engineers from the Boston space, was awarded the $15,000 runner-up prize for his or her inventive and mechanically elegant strategy to certainly one of warehouse automation’s most persistent challenges: dealing with giant, heavy, and irregularly formed packages in tight areas.

Their answer targeted on end-of-arm instrument innovation, presenting a novel, low-profile gripper able to adapting to deformable and variably stacked objects with minimal pre-alignment. By emphasizing mechanical compliance and passive alignment methods, Breezey’s design achieved safe grasps with out relying closely on high-precision imaginative and prescient or complicated management algorithms.

The workforce additionally demonstrated considerate consideration of integration, proposing a modular arm-mounted system that may very well be retrofitted to current cell platforms or used inside compact cell configurations. Their submission stood out for its practicality, manufacturability, and the potential to function a sturdy subsystem inside bigger automation workflows.

Breezey’s ingenuity and a focus to real-world constraints exemplified the sort of focused, systems-level pondering the CHAMP Problem aimed to foster.