After greater than 300 palletizing deployments in 2025—and over 900 Lean Palletizing items now working in manufacturing—we noticed a transparent sample emerge.

The producers who succeeded didn’t have good information, limitless budgets, or robotics groups on standby. What they’d was readability: on their ache, their priorities, and their willingness to start out.

Right here’s what 2025 taught us about palletizing automation and what it means for those who’re contemplating your first transfer.

And for those who choose watching over studying, you may get these insights together with video case research from SC Johnson, Coca-Cola, and Korea Filter Engineering in our webinar replay.

1. Labor challenges aren’t short-term. They’re structural.

By 2025, labor shortages stopped being a danger and have become an working situation.

Throughout meals, beverage, and shopper items, producers informed us the identical story:

- Power problem staffing palletizing function

- Excessive turnover on repetitive end-of-line duties

- Rising reliance on additional time or short-term labor

The lesson was blunt: cobot palletizing protects manufacturing continuity. It doesn’t remedy hiring—however it removes your most fragile dependency from the equation.

2. Security strikes tasks sooner than productiveness ever will

Many producers assume automation choices are pushed by throughput. In actuality, security unlocked approvals sooner than productiveness good points.

Tasks moved quickest when:

-

Ergonomic dangers have been clearly documented

-

HSE and HR have been concerned early

-

Palletizing was framed as a long-term security funding

In 2025, the quickest tasks didn’t begin with cycle occasions. They began with folks.

3. ROI works finest when it’s framed as value avoidance

Successful tasks didn’t “show ROI later.” They quantified it upfront.

Profitable groups got here ready with:

- Labor value per shift

- Annual value of staffing a palletizing station

- Additional time, turnover, and injury-related prices

Tasks that stalled usually lacked a monetary baseline or a transparent proprietor. The takeaway: ROI framed as value avoidance succeeds, particularly with operations and finance stakeholders.

4. One line beats a factory-wide plan

Ambition killed extra tasks than finances.

Producers who succeeded began with:

- One line

- One product household

- One clear drawback to unravel

They deployed, discovered, stabilized—and solely then scaled. Ready for the “good” factory-wide resolution persistently delayed progress. In 2025, momentum beat perfection each time.

5. Possession issues greater than expertise

Some stalled tasks had the suitable robotic, the suitable utility, and the suitable companion. What they didn’t have was possession.

Profitable palletizing tasks had:

- A named sponsor

- A transparent decision-maker

- A timeline tied to actual operational strain

Automation handled as a “nice-to-have” hardly ever moved ahead. Selections have to be owned to maneuver.

6. Most palletizing functions are already cobot-ready

One of many greatest surprises from 2025: what number of producers already certified for cobot palletizing.

In case your utility appears to be like like this:

- Instances between 1–35 kg (1–77 lbs)

- Commonplace pallets (48×40 or Euro)

- Steady end-of-line circulation

- Exhausting-to-staff palletizing function

You’re probably decrease danger than you assume. For a lot of vegetation, the barrier wasn’t feasibility—it was notion.

7. Finish-of-line is the place ache concentrates

Palletizing persistently delivered the quickest aid as a result of:

- It’s hardest to employees

- It carries excessive ergonomic danger

- It’s remoted from upstream processes

In comparison with automating earlier manufacturing steps, end-of-line palletizing minimized disruption whereas delivering fast operational affect.

8. Ready for development is a dropping technique

A standard hesitation we heard: “We’ll automate when volumes improve.”

In actuality, labor constraints hit earlier than development does. Producers who automated early used palletizing to:

- Allow development

- Take in demand spikes

- Keep away from future bottlenecks

Those that waited usually discovered themselves reacting underneath strain. In 2025, automation labored finest as a development enabler, not a final resort.

9. Flexibility beats peak velocity

Producers routinely overestimated how briskly they wanted to palletize.

What truly mattered:

- Dependable uptime

- Straightforward changeovers

- Operators who felt assured working the system

Peak velocity regarded good on paper. Dependable flexibility received on the ground.

10. Cobot palletizing works finest as an operational software

Probably the most profitable producers stopped treating palletizing as a one-off automation venture.

As a substitute, they handled cobots like:

- Commonplace manufacturing tools

- A security and workforce stability asset

- A protracted-term a part of their working mannequin

When palletizing felt complicated and dangerous, adoption suffered. When it felt acquainted and usable, it caught.

Bonus classes that modified minds

Integration worry is greater than the actual integration effort.

Most deployments occurred in 1–3 days, not weeks, with minimal upstream modifications and lighter IT involvement than anticipated.

Downtime danger issues greater than capital value.

Executives targeted much less on CapEx and extra on missed shipments, additional time, and publicity when labor didn’t present up.

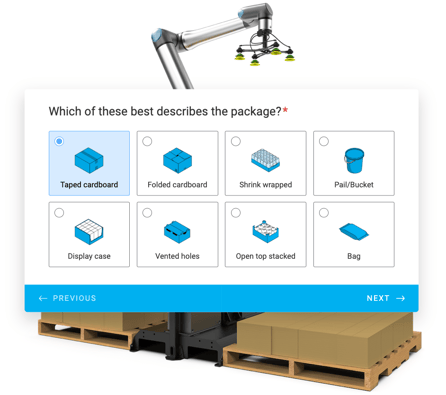

Ease of use determines long-term success.

Operators—not engineers—run palletizers day by day. Easy interfaces and quick coaching persistently outperformed superior options.

The widespread place to begin

Producers who moved ahead sometimes started with:

- One line, one product household

- A easy ROI estimate (labor + security)

- A low-risk feasibility examine

- Clear possession and a timeline

The lesson from 2025 is evident: palletizing automation doesn’t have to be complicated to be efficient. It must be grounded in actual operational ache—and designed for the individuals who run it day by day.

Is Lean Palletizing the suitable match on your manufacturing line?

Not each line has the identical necessities. Payload, cycle time, SKU combine, and accessible house all matter.

Use Robotiq’s Palletizing Match Device to rapidly assess whether or not cobot palletizing is sensible on your operation and what a sensible deployment may appear like on your facility.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the most recent breakthroughs, get unique updates, and join with a world community of future-focused thinkers.

Unlock tomorrow’s developments right this moment: learn extra, subscribe to our e-newsletter, and develop into a part of the NextTech group at NextTech-news.com