We’re thrilled to have fun the excellent achievements of our Jumpstart Fellows! The experiences and accomplishments shared by our Cohort 5 college students show the transformative energy of hands-on studying and business mentorship. Their tales validate our mission and spotlight the unimaginable impression that forward-thinking firms can have after they spend money on the subsequent technology of tech expertise.

The Jumpstart program creates pathways for various highschool ladies to find and pursue robotics careers whereas constructing a extra inclusive tech workforce. By means of complete technical coaching {and professional} mentorship, we equip college students with each the arduous abilities and business connections they should navigate their future careers in expertise confidently.

Program Highlights

Our intensive curriculum for cohort 5 ran each Saturday from January by way of Might 2025, together with classes throughout February faculty trip. College students gained hands-on expertise in:

- Design and fabrication methods

- Electronics and engineering fundamentals

- Programming and coding purposes

- Skilled growth and networking abilities

- Office communication and collaboration

Actual-World Expertise: In August 2025, our Fellows introduced their summer season internship experiences to a multi-cohort viewers, together with their employer mentors. These displays showcased not simply what they discovered, however how they contributed meaningfully to their host firms.

Trade Partnership Influence

Our companion firms didn’t simply present internships—they created real skilled experiences that handled our Fellows as valued staff members. These organizations acknowledged the potential in our college students and supplied mentorship that may affect their profession trajectories for years to return. Please take time to study extra in regards to the firms and the expertise from the fellows perspective.

We lengthen our deepest gratitude to each firm that welcomed Jumpstart Fellows as summer season interns. Your dedication to nurturing younger expertise and your funding in constructing a various tech workforce make these transformative experiences attainable. The mentorship and real-world expertise you present are constructing the muse for the subsequent technology of robotics innovators.

We’re particularly proud to spotlight GreenSight, a founding companion and longtime collaborator of the Jumpstart program. Their unwavering dedication to our mission is obvious of their constant help, internet hosting a number of interns yearly, and even welcoming again returning Fellows from earlier cohorts! This summer season, GreenSight opened its doorways to 3 of our proficient interns, offering them with significant skilled experiences that construct instantly on their Jumpstart coaching.

Collective Introduction to Greensight

GreenSight, based in 2015 and primarily based in Charlestown, Boston, is an revolutionary robotics and aerial intelligence firm specializing within the fast UAS growth for each industrial and navy purposes. With a portfolio that integrates autonomous drones, proprietary multispectral sensors, and AI-driven analytics, GreenSight delivers actionable insights throughout sectors like agriculture, turf administration, and environmental monitoring. On the core of its philosophy is UltraBlue, a centralized flight management system that, together with in-house manufacturing and tightly built-in subsystems, permits GreenSight to quickly prototype and deploy cohesive, adaptable robotic options.

Fellow Reflections

Priyani (Essex North Shore Agriculture & Technical College, a rising freshman at Northeastern College)

Throughout my time as a Jumpstart Intern at Greensight, I explored the software program engineering elements. Particularly, the vast majority of the brand new abilities I discovered have been for our intern mission, Jumpstart Aerial Marsupial Deployment (JAMD). I labored on determining laptop vision-based touchdown, configuring a brand new radio digital camera system, serving to design UIs, and making an attempt to get a robotics physics simulator operating to function drones nearly.

Moreover, I’ve additionally been capable of study extra abilities in 3D printing, machine studying, and Arduino, gaining extra expertise in programming and engineering. General, I’ve been capable of uncover a large set of subjects that I might by no means have been capable of broaden upon until in a real-world setting like Greensight. I’m very grateful to all of the welcoming individuals who make up Greensight for serving to us study and develop a lot and permitting for such an impactful alternative. Particularly, I want to thank my mentor Emily for her help, and Jonathan for main and guiding us by way of JAMD.

Reem (Pioneer Constitution College of Science 1, a rising senior)

Interning at Greensight opened up my eyes to the company life and aspect of engineering. From the get-go go I used to be instantly immersed in initiatives or duties the place I utilized the machine store, CAD, 3D-Printing, or just sketched out attainable options in commerce research. I primarily labored on our intern mission, Jumpstart Aerial Marsupial Deployment, or JAMD, the place I discovered a brand new CAD program known as Onshape. I used to be beforehand unfamiliar with CAD past the fundamentals of SolidWorks, so taking these Onshape programs and studying how one can use this system considerably enhanced my technical and mechanical abilities. On this mission, we additionally carried out a commerce examine the place I drew out sketches for attainable designs that might later be created in CAD.

Moreover, I used to be granted the chance by Maria to take part in a STEM Training mission known as SeaJellys. On this bioinspired mission, the silicone aquatic robotic used water to activate the actuators and transfer the biomimetic jellyfish within the water. I contributed to this mission in a really significant manner and got here again to Massrobotics BlueTech Academy to assist others construct, admire, and study from the SeaJelly mission. I additionally linked with quite a lot of the individuals and engaged in purposeful conversations. All in all, working at Greensight has been a really enjoyable and rewarding course of. Everyone seems to be keen to assist or add you to initiatives, and that’s one thing I really admire within the workspace. Subsequently, I wish to thank Maria, who allowed me to work on the SeaJelly mission together with her and at all times made me really feel included. Our staff lead for JAMD, Jonathan, for at all times being keen to assist me out, clarify issues to me, and, most significantly, cope with my jokes.

Abi (Arlington Excessive College, rising Senior)

Whereas interning at Greensight I’ve labored with a number of initiatives however particularly on the mechanical engineering aspect of our intern mission, Jumpstart Aerial Marsupial Deployment (JAMD). I’ve begun studying a brand new CAD program, Onshape, and increasing my information and abilities with CAD packages. I’ve additionally grow to be accustomed to utilizing 3D printing and fast prototyping with the intention to shortly iterate on designs and produce last merchandise. Primarily, I’ve been placing collectively a commerce examine for varied mechanisms. Every model has been iterated and streamlined to be as environment friendly as attainable, and can be examined in varied methods in addition to in several supplies to slender down choices with the objective of discovering the only and handiest model of the mechanism.

My Greensight internship has been an unimaginable alternative to expertise how initiatives are run within the company world, in addition to to work with and study from engineers with years of expertise. I want to thank the individuals of Greensight for being so welcoming and keen to assist, and particularly my mentor, Ben, for his help, in addition to the JAMD staff lead Jonathan for his steering and help in our mission.

WSP USA inc. good points their popularity as a strategic, entrusted, and various group of pros by way of their globally acknowledged engineering and design companies that not solely help their firm’s objective to “create optimistic, long-lasting impacts” on the communities they serve, but additionally show their dedication and acceptance of the individuals who rely on them, like Aliana and I.

Jasmine (Ruth Batson Academy, rising freshman at Northeastern College)

Throughout this internship at WSP, we’ve shadowed numerous engineers, studying about careers I beforehand didn’t know of, however which might be essential for the continual development of our modern-day constructions and surroundings.

Some memorable moments are the positioning visits I accompanied them on; one to Boston Faculty for his or her Catholic archive constructing and one other to the South Station tower. It was fascinating to witness the totally different phases of engineering of each, as one had not more than concrete and rebar. The opposite was solely constructed and within the strategy of getting electrical, hearth security, and plumbing work accomplished. Accompanying MEP (mechanical, electrical, and plumbing) engineers, in addition to structural engineers, of their inspection of their creations opened my eyes to intricate particulars inside a constructing one wouldn’t usually discover. Surrounding myself with engineers whom I may relate to solely strengthened my curiosity about learning engineering in my larger training.

Aliana (Boston Latin College, rising senior)

I interned at WSP USA Inc., a worldwide engineering consulting agency with a future-oriented imaginative and prescient and locally-minded impression. WSP covers all the pieces—property and buildings, the earth and the surroundings, transportation, water, power, and advisory companies. Some notable initiatives WSP has led embody the Lindemann Performing Arts Middle, notable for its cell inside, which might develop and shrink in dimension relying on the efficiency ambiance whereas remaining structurally sound; the Adimab lab area, the primary within the area to be constructed with mass timber, a fabric pioneering eco-friendly and sustainable constructions; and the renovation of Rubin Corridor at New York College, a Twenties-era constructing now refurbished to realize a exceptional LEED Platinum degree for sustainable power use. Every of those initiatives is outstanding by itself, and WSP’s completion of every as a single firm displays their pioneering innovation. Past this, WSP Boston’s workplace tradition is welcoming and pleasant, and every workplace focuses on native initiatives related to the realm. General, WSP is exceptional each on a worldwide scale, pioneering constructions for the longer term, and on a neighborhood degree, guaranteeing high quality work on every mission.

The construction of my internship allowed me to shadow in quite a lot of departments inside WSP. I frolicked with many engineers and planners in varied specialised fields: structural, mechanical, electrical, plumbing, and civil engineering; city and transportation planning; and environmental coverage specialists. Experiencing a day as every of those professionals—and asking plenty of questions—was essentially the most impactful a part of this system, because it revealed to me what a profession in engineering entails on a day-to-day foundation. I dove into quite a lot of structural initiatives, from workplace buildings to hospitals, and even received to accompany three building website visits. With many because of all the great WSP professionals I shadowed and discovered from, I’ve come away from this summer season with a greater understanding of the world after academia, and a fantastic pleasure for the longer term.

Aadya (Burlington Excessive College, rising senior)

ADI Federal is a specialised division of Analog Gadgets, Inc. (ADI) devoted to serving U.S. protection and nationwide safety missions. ADI delivers superior analog, mixed-signal, and digital sign processing options tailor-made for navy and aerospace purposes. The corporate performs a vital function in enabling mission success by way of precision engineering, rugged {hardware}, and safe programs designed to carry out in essentially the most demanding environments. Working at ADI Federal means contributing on to initiatives that help the protection and technological superiority of the U.S. navy.

As a Course of-Sustaining Engineering Technician at Analog Gadgets, I supported the event and optimization of producing processes by way of a mixture of hands-on technical work and digital design. I labored extensively with SolidWorks to create and modify 3D fashions utilized in tooling and fixture designs for product testing and meeting. My work additionally included collaborating with engineers on course of enhancements, troubleshooting gear points, and validating designs in real-time to make sure excessive effectivity and high quality in manufacturing. This function gave me the chance to use each artistic problem-solving and technical abilities in a fast-paced, innovation-driven surroundings.

Vaishnavi (Chelmsford Excessive College, rising senior)

This summer season, I interned at Analog Gadgets, an organization specializing in semiconductor manufacturing and engineering options. Analog Gadgets performs an important function within the electronics business, and the placement I interned at works on the design, testing, and manufacturing of elements that help superior expertise throughout varied fields. The corporate’s dedication to innovation and precision provided me the right surroundings to discover the intersection of engineering, manufacturing, and company operations.

Throughout my internship, I labored on a spread of technical and organizational initiatives that gave me hands-on expertise in each mechanical and course of engineering. I contributed to PIND (Particle Influence Noise Detection) calculations, investigated a quartz-related challenge in a producing line, and helped design a chem movie tray for a reference technology mannequin utilizing SolidWorks. Certainly one of my key duties was organizing the Manufacturing Execution System (MES) to enhance workflow readability and construction. These initiatives helped me strengthen my technical abilities, achieve a deeper understanding of manufacturing programs, and see firsthand how engineering ideas are utilized in a real-world company setting.

Alexis (Lowell Excessive College, rising freshman at UMASS Lowell)

In the meanwhile I’m an intern at UMass Lowell, a Carnegie Analysis (R1) college. They supply their college students entry to hands-on analysis alternatives, co-ops, and state-of-the-art labs. The college is well-known for his or her STEM training, particularly their laptop science, engineering, and robotics departments. They domesticate an surroundings targeted on encouraging innovation and significant pondering for the better good. Though I’ve solely began working for a few week now. I’ve discovered a lot from my professors, offering me the help to grow to be impartial and additional develop my abilities in engineering.

I’ve began my analysis targeted on Kiss Institute for Sensible Robotics (KIPR) and their Wombat mannequin. Not solely have I began to study the C programming language, I’ve additionally discovered how one can take a look at varied servos and motors. Testing the electromechanical elements, I’ve acknowledged their capabilities and methods to govern it for my upcoming private initiatives. By means of these acts I’ve learnt the significance of upkeeping my supplies, whereas managing my time successfully by way of our brief program. These abilities can be priceless to my future, not simply as an engineer, but additionally as an individual.

I can’t wait to proceed working at UMass Lowell beneath the help of my professors Sam Reig and Maru Cabrera. The accessible state-of-the-art labs and warming surroundings has me excited for future initiatives. I’m grateful to UMass Lowell and MassRobotics for this capability to proceed engaged on campus till my first semester.

Vanessa (Arlington Excessive College, a rising freshman at McGill College)

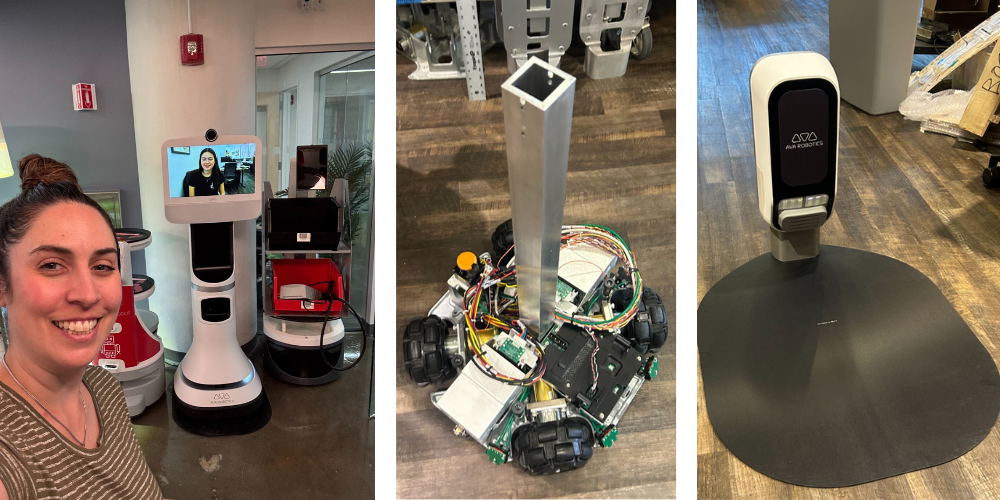

AVA Robotics is an organization that produces and manufactures clever robots utilized in varied areas, together with healthcare, training, manufacturing, retail, and finance. The corporate values teamwork, and there may be at all times collaboration between staff, whether or not it’s to assist construct one thing or remedy a problem with the robotic.

At AVA Robotics, I primarily labored on constructing components of the robotic. For example, I’ve constructed the bottom and charging station of the robotic from scratch. Moreover, I’ve helped take aside previous robots to scrub and restore them after they’ve returned from a consumer.

Elka (Arlington Excessive College, a rising freshman on the College of Maryland)

Well known because the chief within the automotive digital camera meeting and testing. ASMPT AEi develops revolutionary options for energetic alignment meeting and has supplied state-of-the-art programs for exams and calibration.

I designed & prototyped a mechanical fixture for UV energy measurement; Created quite a few CAD fashions, assemblies, BOMs, and superior engineering drawings in SolidWorks; Produced 3D-printed prototypes that went by way of many iterations and enhancements earlier than turning into finalized components for machining; Realized and utilized key mechanical design ideas together with tolerance stack-ups, mechanical incrementing methods, and precision alignment methods; Created detailed handbook for operators, technicians, and engineers & those that are accountable for UV course of setup, verification, upkeep, and troubleshooting; Made use of many superior instruments akin to an Arbor press, a soldering iron and so forth; Delivered an answer tailor-made to firm wants.

I beloved with the ability to CAD all day and switch my concepts, sketches, and 3D modeling design concepts right into a tangible last product. It challenged and sharpened my abilities in massive top-level assemblies, design for manufacturing, skilled engineering drawings & way more. This internship helped reaffirm my mechanical engineering main alternative and profession path. As well as, I received to look at first-hand several types of engineers and the way all of them have their totally different duties within the workplace primarily based on their experience. I’m very grateful for the chance to get such worthwhile hands-on work expertise {and professional} steering.

AccuRounds is a producing firm that focuses on making tight-tolerance cylindrical components utilizing high-precision equipment. Through the use of collaborative robots (Cobots), AccuRounds has automated its total machining course of from starting to finish, requiring minimal help from human operators to keep up the equipment in the long run.

Kelley(Randolph Excessive College, rising senior)

As a course of engineering intern, I had the chance to work on a mission targeted on bettering the design of a gripper hooked up to one of many cobots, beneath the mentorship of course of engineer Mat Pham, and in collaboration with MR fellow Sarah Hegazi. The issue with the gripper was that over time, the sharp fringe of the machined half would put on down the within of the gripper, making it ineffective in its process of choosing and putting completed machined components from a conveyor belt onto a tray. Utilizing CAD software program, 3D modeling, and robotic programming, I went by way of a number of rounds of measuring, modeling, printing, and testing to design a completely new system for the conveyor belt to make sure my grippers operated effectively. Alongside a redesigned gripper, the ultimate mannequin included a number of fences that guided the machined half into an optimum place. By creating this new conveyor belt configuration, I additionally utilized my coding abilities to reprogram the Cobot to include the most recent updates.

In the end, I had a fantastic expertise interning at AccuRounds. This internship gave me invaluable real-world expertise, permitting me to use and strengthen the abilities I’ve developed by way of previous initiatives and the fellowship program. I discovered quite a bit about automation and the way the manufacturing business is constant to evolve and make the most of new applied sciences to enhance its programs. It gave me a glimpse of what a job in engineering would possibly entail and the duties that an engineer performs day-to-day. Popping out of this internship, I can say with confidence that this was a fantastic internship expertise. The talents I discovered throughout my time right here will stick with me as I discover different alternatives. Thanks to MassRobotics, particularly Alethea and Kevin, for giving me this chance, and thanks to Mat for mentoring me!

Conclusion:

We lengthen our deepest gratitude to each firm that welcomed Jumpstart Fellows as summer season interns. Your dedication to nurturing younger expertise and your funding in constructing a various tech workforce make these transformative experiences attainable. The mentorship and real-world expertise you present are constructing the muse for the subsequent technology of robotics innovators.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the most recent breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s developments at present: learn extra, subscribe to our publication, and grow to be a part of the NextTech group at NextTech-news.com