Should you work in manufacturing, manufacturing, or logistics, a giant a part of your end-of-line course of might be palletizing. However a query stays: with all of the choices out there within the palletizing market, which palletizer is true for your enterprise?

Contemplating elements like house out there in your facility, funds, velocity and throughput wants, this text will dive into which palletizers can do what, and which one is true for your enterprise.

What’s a robotic palletizer?

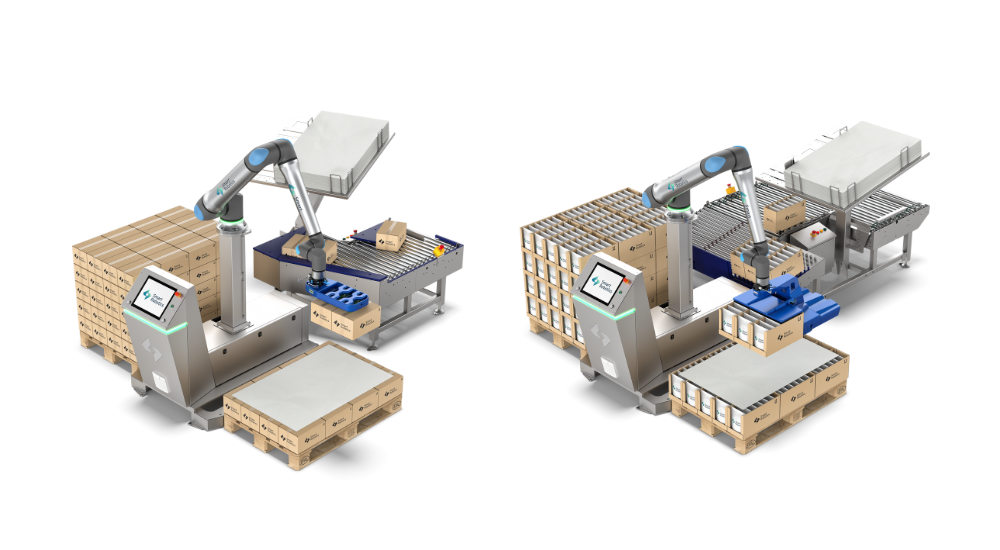

A robotic palletizer is an automatic system that makes use of a robotic arm to stack merchandise corresponding to containers, cartons or luggage onto a pallet. The system combines clever software program with exact {hardware} to grip, elevate and place objects in an outlined stacking sample, providing a versatile and environment friendly resolution for end-of-line automation.

Key options of a robotic palletizer:

Robotic arm: To stack merchandise neatly and reliably, a 6-axis robotic arm is usually used. It provides the flexibleness wanted to maneuver and orient every product into the precise place on the pallet.

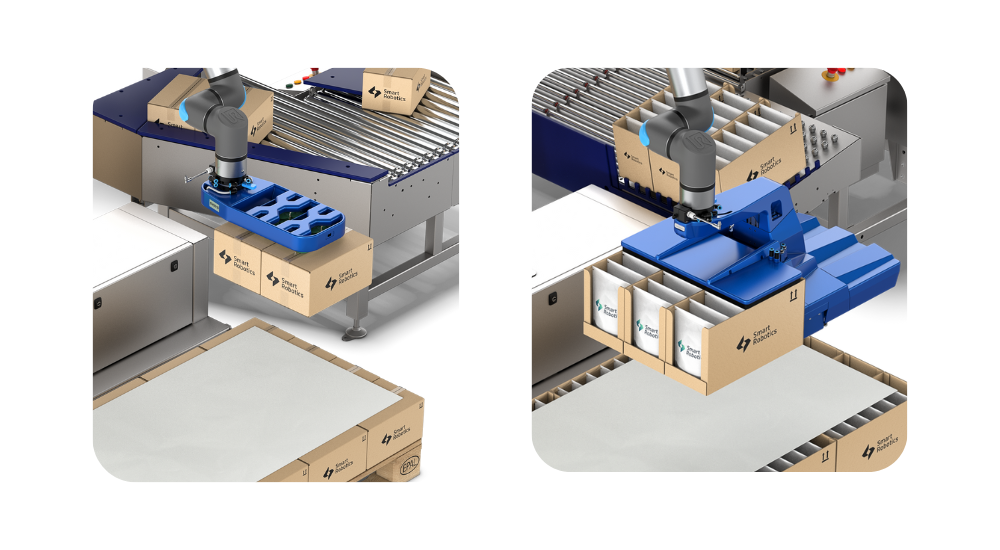

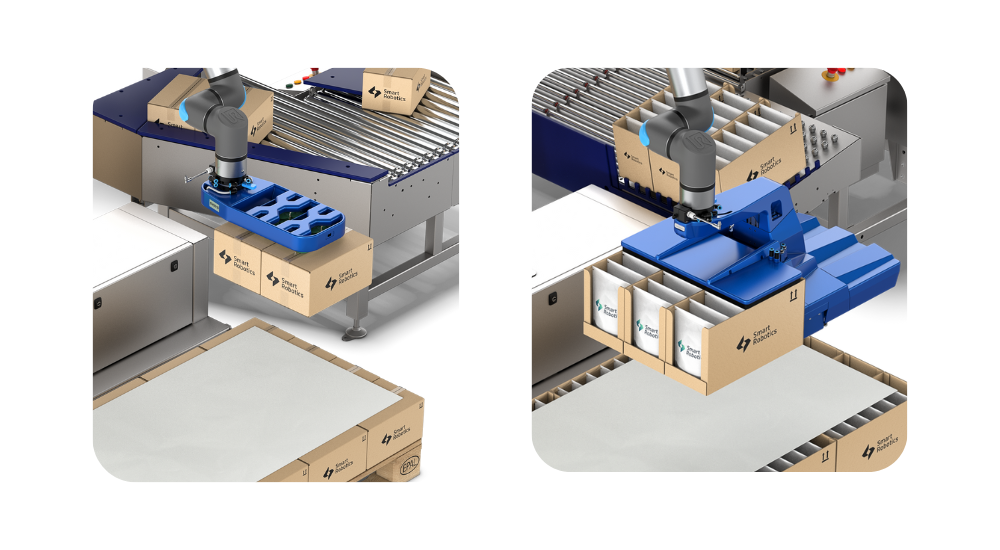

Gripper end-effector: Sometimes called the hand of the robotic, the end-effector gripper makes use of suction to elevate merchandise. Most robotic palletizers use both a vacuum or forklift-type gripper to deal with various kinds of instances, whether or not they’re open, closed, taped, or glued.

Sensors: Robotic palletizers use AI-driven sensors to keep away from collisions and deal with merchandise gently. Power and proximity sensors assist the robotic perceive how firmly to grip a field and the way shut it’s to the product earlier than selecting it up.

Software program: Each palletizing system depends on software program to manage the robotic’s actions. These actions are configured based mostly on product measurement, weight, stacking sample, and any particular palletizing wants.

At Good Robotics, we’ve developed our software program in-house to provide prospects full flexibility, whether or not they want a single setup at present or wish to scale and adapt sooner or later.

What’s a gantry palletizer?

Not like robotic palletizers, gantry palletizers use elements like conveyors and pushers to rearrange objects into layers earlier than stacking them on a pallet.

They’re usually constructed for high-throughput palletizing (typically 2,000 instances per hour or extra) and work finest with merchandise that keep the identical in measurement and weight. But when something modifications, just like the product dimensions or stacking sample, reconfiguring the system is normally complicated and takes time.

Key elements of gantry palletizers:

Body: The body is the mounted construction that helps and permits the motion of the system alongside the X, Y, and Z axes. Usually, it’s put in above the work space to provide the gantry entry to a number of pallet positions throughout the workspace.

Linear drive system: This method controls the linear actions of the gripper or software head.

Gripper: The gripper is called the “hand” of the machine. Most gantry techniques use a vacuum or clamp-style gripper to select up merchandise and place them onto the pallet.

Product infeed conveyor: This conveyor strikes merchandise to the pickup zone. It really works in sync with the gantry to ensure every merchandise is in the precise place on the proper time.

Pallet station: That is the place the gantry stacks merchandise. Some techniques assist a number of pallet stations to scale back downtime.

Controls and software program: The software program manages the whole lot from motion to stacking patterns and system configurations. It’s the core of the operation and could be adjusted to match your particular palletizing wants.

Security space: Gantry palletizers usually are not collaborative techniques, in order that they require security fencing or limitations across the work space to guard operators throughout operation.

What are the professionals and cons of robotic palletizers?

Now that we’ve coated what robotic palletizers can do, it’s price the advantages and downsides of utilizing one.

Advantages of a robotic palletizer

Extremely versatile techniques: Robotic palletizers adapt simply to modifications in product measurement, weight, or stacking sample. Should you introduce a brand new SKU or swap to a heavier field, the system could be shortly reprogrammed to deal with it with no gantry modifications wanted.

Small footprint palletizer: In comparison with gantry palletizers, robotic palletizers take up far much less house. A typical setup matches inside 2.5 x 3 meters, whereas gantry palletizers typically want 8 x 5 meters or extra. That bigger footprint consists of the house wanted for layer-forming zones, pushers, conveyors, and security entry areas.

A typical setup matches inside 2.5 x 3 meters, whereas gantry palletizers typically want 8 x 5 meters or extra. That bigger footprint consists of the house wanted for layer-forming zones, pushers, conveyors, and security entry areas.

Security: Robotic palletizers that use collaborative functions adjust to ISO 10218-2 and are secure to make use of.

They decelerate when somebody comes shut and cease if they arrive into contact with something sudden, like an operator. In addition they cut back the necessity for guide selecting and inserting, which helps stop pressure and again accidents on the work flooring.

Decrease upkeep and prices: Robotic techniques are compact, have fewer shifting components (like pushers and conveyors), and run on easier software program in comparison with gantry machines. Consequently, they expertise much less put on and tear and usually require much less upkeep over time.

Drawbacks to proudly owning a robotic palletizer:

Value of funding and operation: Each gantry and robotic palletizers require an identical upfront funding, although robotic techniques usually value much less to take care of over time. Robotic techniques additionally take up much less house and are simpler to adapt, which helps cut back the general value of possession.

Requires skilled setup: To arrange a robotic palletizer correctly, programming experience is required.

At Good Robotics, our service crew handles that from begin to end. From the second the system is permitted to the second it’s up and operating on the buyer’s web site, the crew makes certain the whole lot works because it ought to and stays that method.

Payload limitations: Robotic palletizers utilizing cobot functions usually deal with as much as 30 kg per product.

That’s greater than sufficient for many operations. But when you’ll want to elevate merchandise heavier than that, you possibly can look into mixed-case palletizers which are designed for increased payloads and stacking totally different product varieties on a single pallet.

Gantry palletizers are additionally an possibility, however they don’t supply the identical flexibility as robotic or cobot techniques.

Robotic palletizers vs gantry palletizers

In comparison with conventional gantry palletizers, robotic palletizers supply a much more versatile and space-efficient resolution. Whereas gantry techniques are inflexible and restricted of their software, robotic palletizers are simply programmable and extremely adaptable to totally different product varieties and layouts.

They require minimal upkeep, devour much less power, and might ship a return on funding inside 6 months to 2 years, considerably quicker than the two–5 years usually seen with gantry setups. For companies searching for a compact, future-proof palletizing resolution with decrease long-term prices, robotic palletizers supply a sensible possibility.

Which palletizer is true for your enterprise?

Palletizing wants rely in your merchandise, output targets, and the house you’ve out there. Gantry palletizers are sometimes used for high-speed stacking of uniform merchandise, however they’re tough to adapt when merchandise change.

That’s the place robotic and cobot palletizers have the benefit. They will deal with totally different case sizes, stacking patterns, and workflows with minimal setup time. Should you’re scaling up, updating SKUs, or working in a tighter house, a robotic palletizer presents the flexibleness and ease of use that matches most operations at present and tomorrow.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s developments at present: learn extra, subscribe to our e-newsletter, and turn out to be a part of the NextTech neighborhood at NextTech-news.com