Maker Nick Maselli created a fairly first rate laundry folding robotic prototype in beneath 24 hours for a shopper who merely wanted the job executed. He named it Sourccey, and it’s basically a movable, cylindrical field with a dome on high, two articulated arms, and a middle vertical raise to entry objects. Nearly all of the structural elements, from arm components to outer enclosures, have been created utilizing a 3D printer that produced PLA filament. The truth that it might print so shortly permits them to swap objects out all through the construct window.

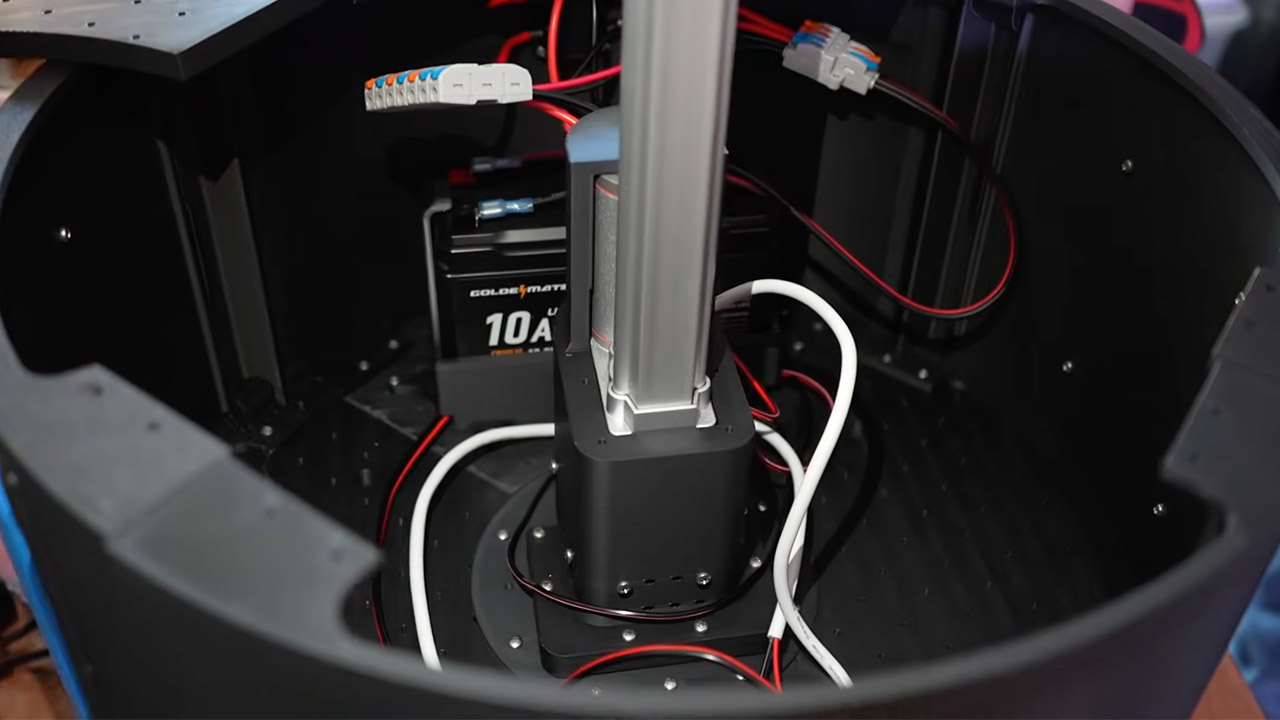

A Raspberry Pi 5 handles all computational duties, together with taking feeds from 4 cameras, controlling the motor drivers, working a show, audio system, and microphone, and overseeing your complete operation. Its energy supply is a 12 volt, 10 amp hour lithium iron phosphate battery, which was chosen for its security and longevity. A customized energy distribution board, mixed with voltage converters, ensures that all the things receives a continuing provide with out overloading.

Unitree G1 Humanoid Robotic(No Secondary Growth)

- Top, width and thickness (standing): 1270x450x200mm Top, width and thickness (folded): 690x450x300mm Weight with battery: approx. 35kg

- Whole freedom (joint motor): 23 Freedom of 1 leg: 6 Waist Freedom: 1 Freedom of 1 arm: 5

- Most knee torque: 90N.m Most arm load: 2kg Calf + thigh size: 0.6m Arm arm span: approx. 0.45m Additional giant joint motion house Lumbar Z-axis…

To realize correct folding, the arms use a number of servos for extremely exact, coordinated movement. A vertical Z-axis actuator runs by way of the middle, permitting the arms to succeed in up and seize objects from the ground or a desk. The grippers on the ends maintain the material tight. Getting all of stuff sorted requires cautious wiring and security options like as fuses to maintain all the things secure.

The best way it folds a towel or no matter it’s avoids all of the hard-coded stuff and as an alternative depends completely on synthetic intelligence. A human demonstrates the right way to carry out the transfer first, which serves as coaching knowledge for the AI mannequin, which then trains in a single day on a number of highly effective GPUs. As soon as it’s all executed, the mannequin is deployed again to the Raspberry Pi, and Sourccey can then do its factor independently: cameras spot a towel, work out the place it’s and what it appears to be like like, seize it, after which execute the folding sequence it realized on the Pi, however right here’s the factor, it’s not simply robust on this one job, it might deal with the pure give in material as a result of it’s utilizing imaginative and prescient to information the entire course of and realized patterns slightly than simply being informed precisely what

The whole construct took lower than 24 hours, with the {hardware} assembled in the course of the day and the AI coaching going down at evening. There have been just a few hiccups alongside the best way, equivalent to a lacking motor clip that wanted to be resoldered and a faulty 3D-printed bit that wanted to be reprinted, in addition to a few group members calling it a day early, which reduce into their time, however regardless of the frenzy, all the things appeared to work fantastic and the prototype accomplished the duty.

[Source]

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s tendencies at this time: learn extra, subscribe to our publication, and grow to be a part of the NextTech neighborhood at NextTech-news.com