A show that makes use of air energy to remodel our perceptions of screens is a novel idea. Maker Soiboi Mushy got down to create one utilizing solely 3D printing, a small quantity of soppy silicone, and the distinction in air stress between regular and vacuum. The top result’s a 4×4 grid of pixels that gentle up varied patterns and video games, letters, numbers, and even a rudimentary snake recreation animation, all with out the usage of electrical energy.

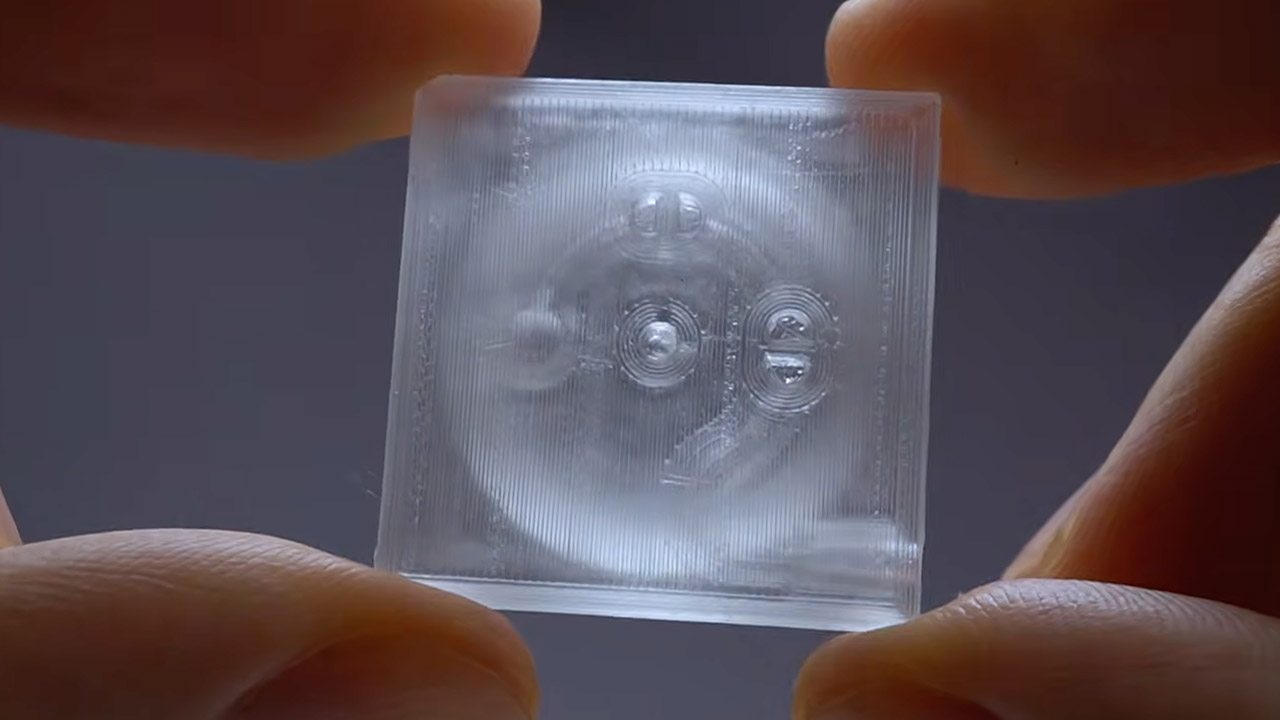

This machine relies on small logic channels carved into clear 3D-printed elements using microfluidics. Every of the 16 pixels consists of a versatile silicone membrane overlaying a small chamber. When a vacuum pushes on the membrane, it drops down, inflicting a noticeable change on the flat floor. In distinction, air stress simply causes the membrane to hold loosely.

Sale

FLASHFORGE Adventurer 5M 3D Printer with Totally Auto Leveling, Max 600mm/s Excessive Pace Printing, 280°C…

- One-Click on Automated Printing: Expertise hassle-free 3D printing with the Adventurer 5M Sequence. Get pleasure from computerized mattress leveling for flawless first…

- 12X Extremely Quick Printing: That includes a CoreXY construction with 600mm/s journey pace and 20000mm/s² acceleration, the AD5M maximizes effectivity, reduces…

- Sensible and Environment friendly Design: Fast 3-second nozzle modifications, a high-flow 32mm³/s nozzle, and quick 35-second warm-up to 200°C ship steady high-speed…

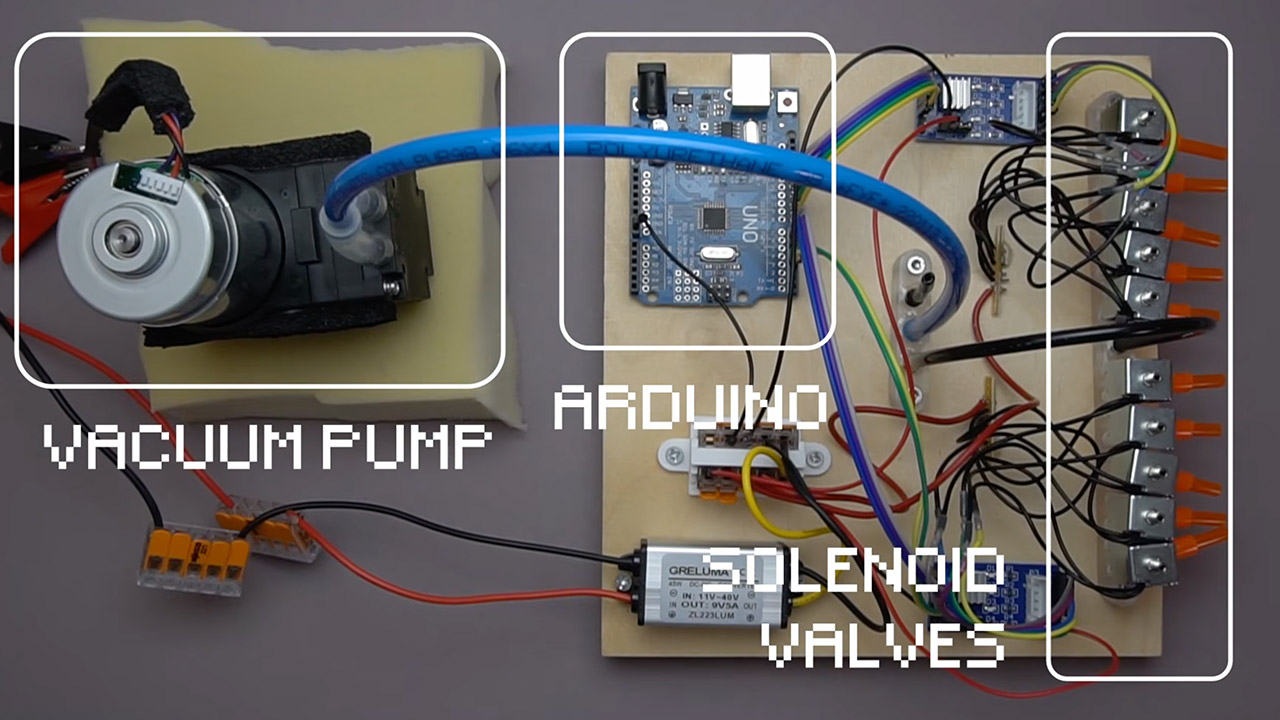

The tough half is determining handle 16 pixels with fewer connections than you’d assume needed. Usually, a full grid would require a separate valve for every pixel, leading to 16 valves and a tangled mess of tubes. Nevertheless, the creator found a a lot easier approach to take action by borrowing from digital shows and use multiplexing. Rows and columns are dealt with by 4 traces every, for a complete of eight management traces. To make sure that solely the proper pixel lights up, every one has an AND gate created from vacuum transistors.

These transistors perform equally to tiny valves within the channels, with three layers: a circulation layer with two unbiased channels resulting in the pixel, a tender silicone membrane within the middle, and a management layer on prime. Whenever you apply a vacuum to the management facet, the membrane slips down, permitting the vacuum to cross by way of. Depart it at regular stress, and the trail will stay tightly shut. Every pixel has two transistors linked in collection, one to the row line and one to the column. Vacuum solely reaches the pixel membrane when each traces pull vacuum concurrently.

As soon as triggered, a pixel maintains its state as a result of the vacuum pulls the membrane down, performing as built-in reminiscence that doesn’t require fixed energy. To clear the show, a 3rd transistor per pixel unites with ambiance, and all of these launch traces join. A quick one-off pulse restores all the pieces to regular and resets the grid for the next sample.

Constructing the total 4×4 model took a while as a result of he needed to rigorously alter settings corresponding to 100% infill, slower print speeds, and aligned patterns. Blunt needles had been hammered into the ports to affix the tubing, and silicone membranes had been molded in frames, minimize to type, and punched to suit between the layers. A central screw strengthens the clamping stress, holding all the pieces hermetic, and UV glue seals the enter ports.

An Arduino exterior the show controls the solenoid valves that change every line between air and a vacuum pump, with easy programming sequencing the pulses to create the required patterns. Early testing on a smaller 2×2 grid helped to clean out difficulties corresponding to latching, and that is ultimately how they resolved the worldwide launch patch.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the newest breakthroughs, get unique updates, and join with a world community of future-focused thinkers.

Unlock tomorrow’s tendencies at present: learn extra, subscribe to our e-newsletter, and turn out to be a part of the NextTech group at NextTech-news.com