An end-effector is the device that sits proper on the finish of a robotic arm, principally, the robotic’s hand. It’s what permits the robotic to work together with its environment. Whether or not it’s gripping, inserting, welding, or scanning, that is the half permits the motion to be fulfilled. For instance, in a pick-and-place setup, the end-effector must seize an merchandise, maintain it securely, and place it precisely the place it must go.

Automation is taking on many repetitive, and infrequently harmful, duties right this moment. Furthermore, the variety of end-effectors obtainable now’s doubtless within the a whole lot, and it’s nonetheless rising. Finish-effectors are getting smarter, extra specialised, and extra adaptive annually.

With that in thoughts, right here’s every little thing you could know concerning the numerous kinds of end-effectors: how they work and the function they play in industrial automation.

What are the kinds of end-effectors utilized in robots?

Finish-effectors typically fall into three fundamental classes: grippers, course of instruments, and sensors. The selection between them relies upon closely on the applying.

Choose-and-place duties often require a kind of gripper, whereas course of instruments are utilized in duties like welding or portray. In fast-moving or unpredictable environments, sensors typically assist end-effectors carry out their jobs higher.

Finish-effector grippers

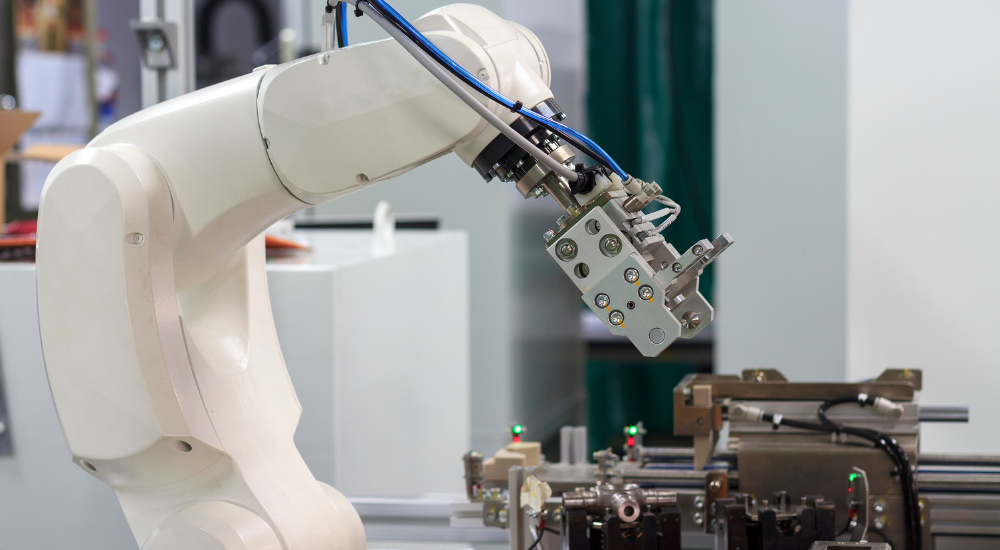

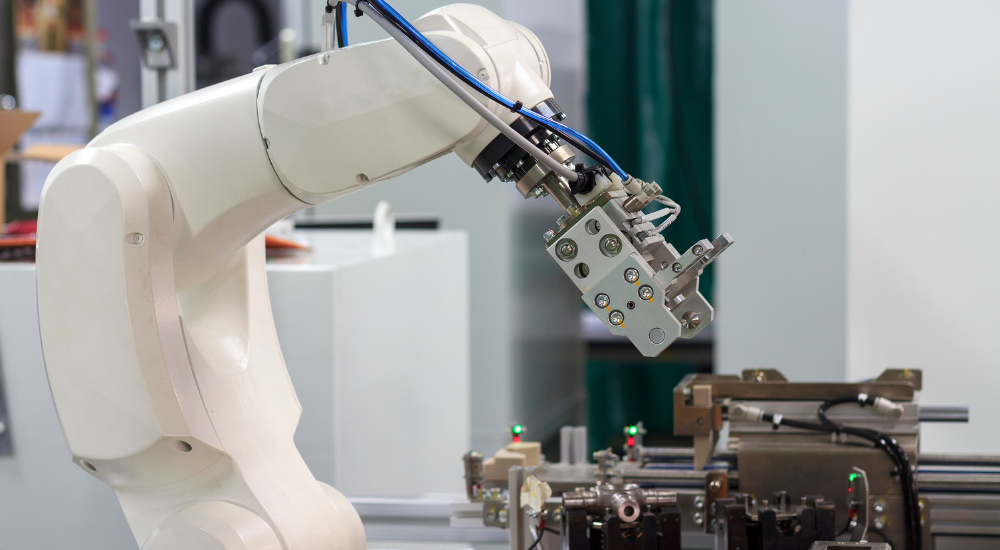

Mechanical Grippers – These are finger-like grippers, just like how a human would choose up an object. They’re extensively utilized in sorting and meeting purposes, transferring merchandise from one place to a different.

- Be aware: Mechanical grippers are easy, dependable, and cost-effective however might not be appropriate for dealing with irregularly formed objects.

Mechanical Gripper

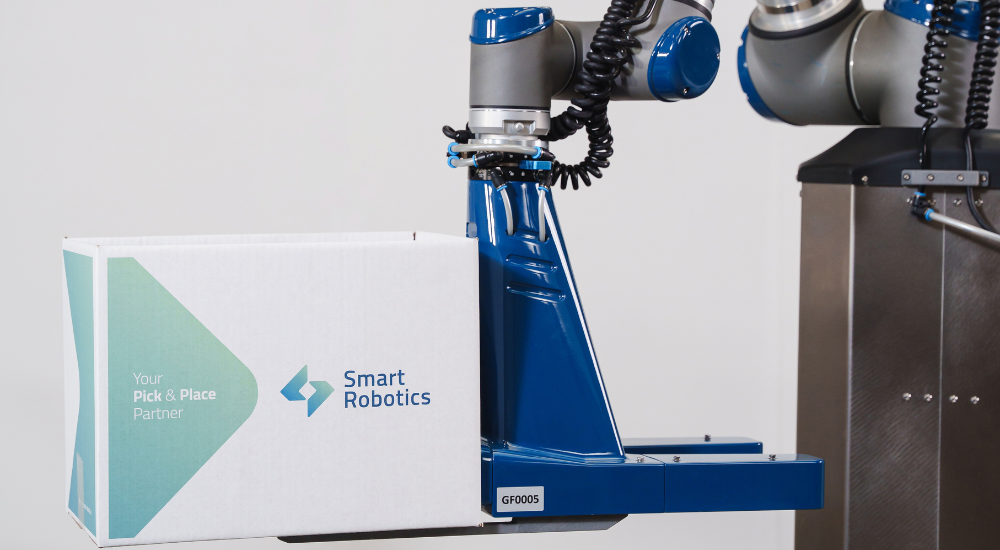

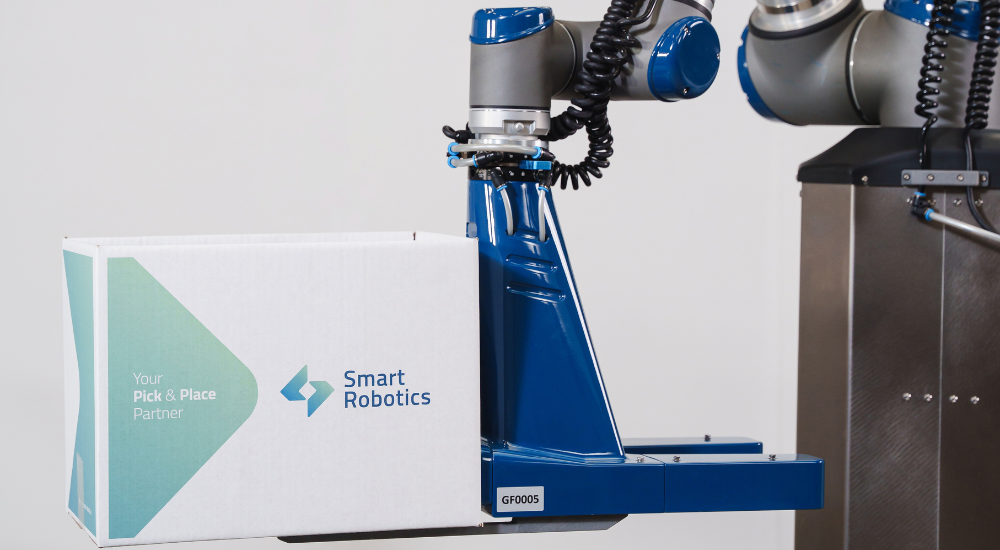

Vacuum Grippers – Utilizing suction cups and vacuum air, these grippers securely elevate merchandise. They grew to become fashionable after mechanical grippers, particularly in industries searching for sooner cycle instances and larger versatility. Purposes like palletizing, depalletizing, and merchandise choosing all depend on vacuum grippers.

- Be aware: Vacuum grippers are simple to make use of, extremely dependable, and have a quick cycle time however might not be appropriate for dealing with heavy or non-porous objects.

Sensible Robotics Vacuum Gripper

Magnetic Grippers – These grippers use magnetic fields to elevate and transport steel elements. As industries like automotive and metalworking expanded, magnetic grippers grew to become important for dealing with ferrous supplies shortly and safely—whereas minimizing the danger of scratches or harm.

- Be aware: Magnetic grippers are extremely dependable and require minimal upkeep however might not be appropriate for dealing with non-ferromagnetic supplies.

Servo Grippers – Not like conventional open/shut grippers, servo grippers permit exact management over grip place and power. This makes them best for dealing with delicate or diversified objects, reminiscent of gentle packaging, electronics, or glassware.

- Be aware: Servo grippers are extremely exact and versatile however could also be costlier and require extra complicated management programs.

Every sort of gripper comes with its strengths and trade-offs. Selecting the best one depends upon the article being dealt with, the required pace and precision, and the work atmosphere.

Sensors in end-effectors

With out sensors, an end-effector is actually a blind device—solely able to repeating pre-programmed actions. However with sensors, robots achieve the power to react to their atmosphere and make selections on the fly. Sensors are notably worthwhile in unstructured or continuously altering environments.

Listed below are essentially the most generally used sensor sorts:

Imaginative and prescient Sensors – These sensors use cameras and 3D scanners to offer the end-effector with crucial visible suggestions—reminiscent of the place to maneuver, what to select (if relevant), and the way the article is oriented. They’re additionally important for navigating environments with out inflicting collisions. This makes imaginative and prescient sensors essential for any utility that requires exact positioning and manipulation, like pick-and-place duties.

Proximity Sensors – These assist detect how shut or far an object is. That provides the robotic the power to pause or alter if it’s nearing a restricted zone, and improves positioning alongside imaginative and prescient knowledge.

Drive/Torque Sensors – These are sometimes built-in into end-effectors to measure how a lot power is being utilized throughout a job. That is important for dealing with delicate objects with out inflicting harm and for performing duties that require a exact quantity of stress.

Mild Sensors – Whereas not as widespread as imaginative and prescient programs, mild sensors can assist alignment and positioning. They detect modifications in mild or floor marks, useful in environments with low visibility or the place edge detection is required.

Magnetic Sensors – These detect magnetic fields and are sometimes utilized in steel dealing with or place monitoring. They’re particularly helpful the place different sensors may wrestle in dusty or low-light settings.

Vary Sensors – These measure the gap between the end-effector and close by objects. That’s helpful for collision avoidance, positioning, or path correction.

Purposes of Finish Effectors

Many duties, particularly these which can be repetitive, hazardous, or tedious, will be automated utilizing robots geared up with end-effectors.

Manufacturing – Finish-effectors are used throughout manufacturing—from meeting duties utilizing mechanical grippers to materials dealing with utilizing suction cups. For instance, robotic arms with course of instruments like welders or drills take over hazardous jobs and depart protected duties for human employees.

Meals and Beverage Trade – Finish-effectors are important in automating packaging, sorting, palletizing, and depalletizing. With the appropriate sensors and grip energy, they will deal with fragile or perishable gadgets with out damaging them. That is key for guaranteeing product high quality and meals security.

Healthcare – In industries like pharma, end-effectors deal with duties reminiscent of packaging remedy or making ready doses with excessive precision, eliminating the danger of human error. In surgical or rehabilitation settings, robotic instruments assist sufferers with mobility workout routines and assist them get again on monitor.

Agriculture – Historically performed by farm employees, duties like harvesting, plant care, and seeding at the moment are being automated utilizing end-effectors designed particularly for agriculture. These instruments typically embody grippers and chopping mechanisms that lightly deal with vegetables and fruit with out inflicting harm. With built-in imaginative and prescient and sensor steerage, they guarantee crops are picked effectively and with care.

Building – In development, end-effectors are used to automate duties which can be often hazardous, reminiscent of bricklaying, welding, drilling, and materials dealing with.

Robotic programs geared up with customized grippers or suction cups can elevate heavy constructing supplies like concrete blocks, glass panels, or metal beams and place them with precision. These instruments enhance security, cut back handbook pressure, and guarantee constant high quality on development websites.

Logistics – Finish-effectors are on the core of recent warehouse automation. Whether or not it’s choosing merchandise off cabinets, inserting gadgets into bins, or palletizing bins, grippers (particularly vacuum-based) pace up processes and cut back human pressure.

Automotive – Robotic programs in automotive rely closely on end-effectors for precision meeting. They’re used to weld automobile frames, set up elements like windshields, and elevate heavy elements of a automobile. Relying on the duty, end-effectors vary from magnetic grippers to welding torches.

How to decide on the appropriate finish effector?

When choosing the right end-effector, all of it comes right down to what the robotic must do and the way it must do it. Right here’s what to bear in mind:

Process necessities: Begin with the fundamentals. What job do you want the robotic to carry out? Selecting, inserting, welding, sorting? What’s the required pace and degree of precision? The solutions will assist you to slim down your choices.

Finish-effector capabilities: When you’re clear on what the end-effector must do, begin trying into which device most closely fits the duty. For instance, if you happen to’re automating a palletizing course of, a vacuum gripper is a superb alternative for sealed or taped circumstances—but it surely gained’t work nicely for crates or open bins.

Wish to discuss it by way of with automation consultants? Guide a name with us right this moment.

Compatibility with the robotic system: The top-effector must combine seamlessly together with your robotic—mechanically, electrically, and thru the management software program. There’s no worth in selecting an excellent end-effector if it doesn’t talk correctly together with your setup.

At Sensible Robotics, we ship full options, together with the robotic arm, software program, body, and end-effector integration, so you possibly can depart that half to us.

Upkeep and restore: Select an end-effector that’s each dependable and simple to take care of. Downtime on a manufacturing line or in a warehouse shortly interprets to misplaced time and income, so sturdiness and ease of servicing are key.

Many programs don’t supply a lot assist after set up, however at Sensible Robotics, we do. Our service crew is obtainable for every little thing from distant diagnostics to on-site troubleshooting, so that you’re by no means left with out assist while you want it.

Value: When choosing an end-effector, it’s essential to look past the upfront worth and contemplate the general worth it brings. Take into consideration how nicely it performs, how lengthy it should final, and what further elements could be wanted for integration.

Additionally consider the price of set up, day by day operation, upkeep, and the potential affect of downtime. The fitting end-effector ought to ship constant, long-term worth—not only a decrease preliminary price.

In brief

Finish-effectors could also be only one a part of your automation system, however they play one of the crucial crucial roles. From exact placement in high-speed palletizing to delicate dealing with in agriculture or pharma, the appropriate end-effector determines how efficient (and dependable) your automation actually is.