As Thanksgiving approaches, we at Robotiq are particularly grateful for the Meals & Beverage producers, operators, engineers, and integrators who work tirelessly on daily basis to maintain manufacturing transferring.

We’re additionally grateful for the facility of good automation: expertise that doesn’t simply enhance output, however protects individuals, improves high quality, and makes factories safer and extra sustainable.

To have a good time, we’re sharing 5 real-world tales the place Robotiq’s collaborative palletizing options have made a significant affect. These examples present what’s attainable when automation and human expertise work hand in hand.

1. Glenhaven Meals: Quick ROI, safer operators

The Problem: Glenhaven Meals confronted excessive labor prices and ergonomic pressure from handbook palletizing of frozen meals. They wanted an answer that might deal with dozens of SKUs with out compromising employee security.

The Answer: By implementing Robotiq’s PE20 Lean Palletizer, Glenhaven Meals automated 15 packing containers per minute throughout 25 SKUs. The system was up and working rapidly, with minimal coaching required.

The Outcome: Operators have been free of repetitive, high-strain duties, productiveness elevated, and the ROI was achieved in simply 13 months. Lean Palletizing grew to become an integral a part of their operations, supporting each output and office security.

2. RAIN Pure Mountain Spring Water: Lowering pressure, boosting throughput

The Problem: RAIN Pure Mountain Spring Water’s operators have been lifting heavy 30-pound packing containers in a compact facility, a bodily demanding process that contributed to fatigue and turnover.

The Answer: Robotiq’s compact palletizing resolution enabled protected, collaborative automation proper alongside human operators.

The Outcome: By way of automation, operators have been reassigned to higher-value duties, throughput elevated, and ergonomic dangers have been considerably decreased. This allowed the crew to concentrate on what issues most: constant high quality and effectivity.

3. Griffith Meals Colombia: Eliminating hundreds of repetitive motions

The Problem: Repetitive handbook stacking was creating fatigue, ergonomic dangers, and slowdowns on a number of manufacturing strains with many SKUs.

The Answer: Lean Palletizing, powered by Robotiq cobots, changed hundreds of each day repetitive motions with automated precision.

The Outcome: Operators now take pleasure in safer, much less bodily demanding work, whereas the manufacturing line runs extra constantly. Security and productiveness went hand in hand, proving that even repetitive, “back-of-line” duties can profit from automation.

4. Panovo (Grupo Proan): Dealing with tall stacks with ease

The Problem: Bakery manufacturing strains confronted excessive pallet stacks (as much as 2.5 meters/ 8+ ft), inflicting fatigue and inconsistent pallet high quality.

The Answer: 5 AX10 cobots have been deployed to deal with palletizing, with fastidiously engineered configurations to handle tall stacks safely.

The Outcome: The cobots constantly stack tall pallets with out fatigue or error, enhancing workflow, operator well-being, and pallet stability. Panovo now runs a smoother operation whereas holding workers out of dangerous handbook duties.

5. Korea Pelagic: Automation in a chilly, demanding surroundings

The Problem: Seafood processing requires dealing with heavy, chilly objects with restricted workforce availability and excessive turnover threat. Guide palletizing was sluggish, unsafe, and inconsistent.

The Answer: Robotiq cobots automated palletizing within the chilly surroundings, working safely alongside people.

The Outcome: Productiveness elevated by 200%, labor pressure decreased, and turnover stabilized. Operators can concentrate on higher-value duties, whereas cobots deal with repetitive, bodily demanding work.

Why these tales matter

Throughout these 5 case research, a couple of clear patterns emerge:

- Automation protects individuals: From heavy lifting to repetitive motions, cobots deal with high-risk duties safely.

- Automation helps enterprise development: Elevated throughput, predictable ROI, and sooner commissioning make these investments worthwhile.

- Automation enhances human expertise: Operators are freed for higher-value work, resulting in safer, extra partaking jobs and decrease turnover.

At Robotiq, we usually share these real-world buyer tales to point out what’s attainable when people and robots work collectively.

A Thanksgiving Message

This vacation season, we’re grateful for all of the Meals & Beverage groups who make innovation, security, and effectivity a actuality.

From Glenhaven Meals’ quick ROI to Korea Pelagic’s cold-environment success, these tales remind us why automation is about greater than machines; it’s about supporting the individuals who make factories thrive.

Right here’s to full pallets, safer workflows, and smarter operations this Thanksgiving.

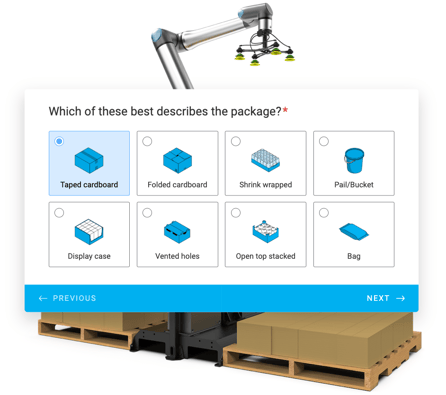

Uncover your personal path to safer, smarter palletizing. Strive the Palletizing Match Device — a fast, interactive solution to see if Lean Palletizing is the proper match in your line.

Need extra tales from actual factories like yours?

Observe Robotiq on LinkedIn and be part of over 75,000 producers seeing how automation retains individuals protected, and manufacturing working sturdy.

Elevate your perspective with NextTech Information, the place innovation meets perception.

Uncover the most recent breakthroughs, get unique updates, and join with a worldwide community of future-focused thinkers.

Unlock tomorrow’s tendencies immediately: learn extra, subscribe to our e-newsletter, and turn out to be a part of the NextTech neighborhood at NextTech-news.com